Implementing a connected gas detection program doesn’t happen overnight. It’s a transformation of your gas detection program, that in the long-term, can help simplify safety, curb risk, and boost productivity.

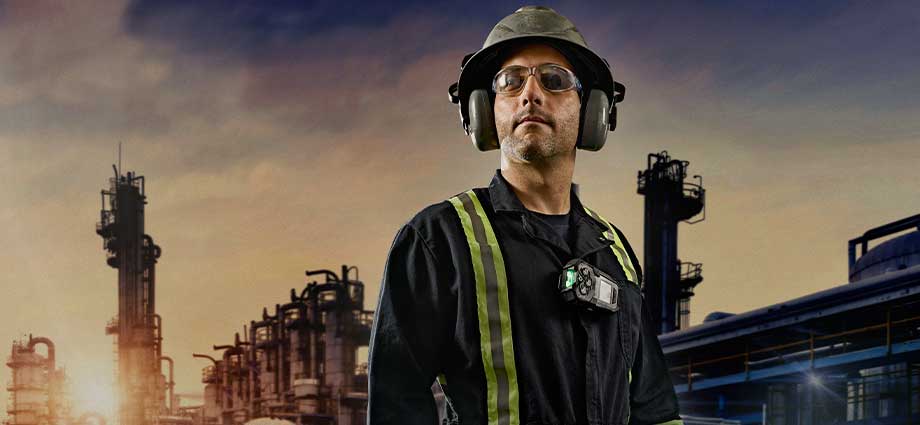

Rimrock Energy, part of the Rimrock Energy Partners, LLC, is a natural gas processing facility in Colorado. Rimrock recently implemented a connected gas detection program – and has experienced positive results.

The team at Rimrock identified some specific challenges with their portable gas detection program that were ultimately leading to growing costs and concern about detector reliability.

Download the case study to learn more.

Download the PDFIn addition, detector deployment and compliance were also a constant challenge, as the fielded devices did not offer convenient ways to understand basic usage and compliance—let alone provide assistance to Rimrock’s lone workers in real time.

To help address these issues, Rimrock implemented a connected safety program, utilizing MSA’s ALTAIR io™ 4 Gas Detection Wearable and Grid cloud-based software.

Initial results of Rimrock’s connected gas detection program include:

- Reducing detector maintenance costs by approximately 75%

- Achieving nearly 100% SOP accuracy

Download the full case study above to learn more about how Rimrock partnered with MSA Safety to help optimize their gas detection program.