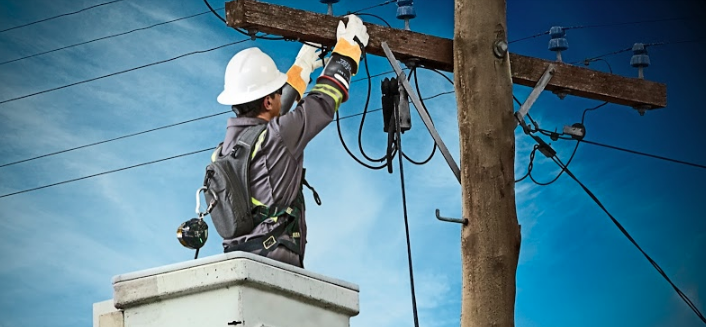

Vigilance: “The careful watch for danger or difficulty.” Almost nowhere is vigilance more important than within the nation’s utility industry. Hazardous working conditions include—but are not limited to—working at height, exposure to high voltage electricity, and confined spaces. Utility company employees who face these challenges, whether occasionally or routinely, can never let down their guard when it comes to their health and safety. For utility safety managers, vigilance means not just knowing the dangers, but preparing for them, too; a manager must keep an eye on both the overall safety plan and its day-to-day implementation. With that in mind, here are three serious oversights that will threaten the effectiveness of a safety program.

1. Generalizing or downplaying the dangers of the job.

What safety manager doesn’t know both the unique and inherent dangers of the work? Sometimes though, often through no fault of their own, the safety manager’s focus shifts from striving for and achieving safety excellence to sorting through and keeping up with confusing standards and changing rules. Of course, OSHA compliance is both sensible and necessary for a “legal” work environment. However, the best practices don’t stop there. A wise safety manager not only understands the general danger and meets basic standards, but considers each risk individually and provides custom safety solutions tailored to the worker and the job at hand. This policy, in turn, cultivates a safety-focused workplace culture, where workers master proper safety protocols and learn how to become their own safety advocates.

2. Not using the right PPE for the job.

Putting a utility worker in the wrong personal protective equipment (PPE) isn’t just a superficial oversight—it’s a potentially harmful or possibly even life-threatening error. Especially in the utility industry, there are far too many hazards—known and unknown—to take a casual approach to selecting PPE. Three of the most common risks are:

- Working alone with nobody to see or hear when help is needed

- Being exposed to high voltage environments

- Doing the job on a ladder or in a bucket at height

With these kinds of dangers, it’s important to choose PPE with care. Selection criteria include:

- Is the PPE designed to protect against specific hazards workers may encounter, such as falls from height, arc flash, or foreign objects entering the eye?

- Does the PPE meet the appropriate ANSI standards?

- Does the PPE fit well, and is it reasonably comfortable to wear?

3. Not taking advantage of PPE innovations.

It’s difficult to keep up with rapidly changing technologies, let alone stay ahead of the innovation curve. That being said, utilities cannot afford to lag behind when it comes to PPE improvements or they risk missing out on opportunities to amplify their safety initiatives. This doesn’t have to be an all-or-nothing proposition, though. There is middle ground: a PPE Acquisition Strategy. Simply put, a PPE Acquisition Strategy is a straightforward plan for when and how to invest in new PPE; when and how to get rid of unreliable, inappropriate, or outmoded PPE; and when and how to stay the current course.

One of the responsibilities of the utility safety manager is to continually look for new and better ways to manage safety. But even with heightened awareness and added attention to the hazards and innovations of the industry, there’s no guarantee an accident won’t happen. However, avoiding the mistakes outlined above tips the scale in favor of keeping electric, natural gas, telecom, steam, water and wastewater workers safer. And that, everyone can agree, is the right move.