All industrial protective hard hats are either Type I or Type II based on ANSI and CSA standards for impact resistance and direction. A hard hat can only have one designation for impact properties. There is no in-between according to these standards.

What is the ANSI standard?

The American National Standard for Industrial Head Protection, ANSI Z89.1-2014, provides industrial hard hat performance and testing requirements, and establishes types and classes of protective helmets to provide employers with hard hat options that provide appropriate protection for hazards present in a given workplace.

ANSI Z89.1-2014 was prepared by members of the International Safety Equipment Association’s (ISEA) Head Protection Group as a revision to the 2009 edition and approved by a consensus review panel comprised of technical experts, unions, construction industry and other user groups, test labs, and certification and government agencies.

Download this guide for quick reference about Type I and Type II hard hats.

Download the GuideWhat Is a Type I Hard Hat?

Type I hard hats based on ANSI and CSA standards are designed to reduce force as a result of an impact to ONLY the top of the head.

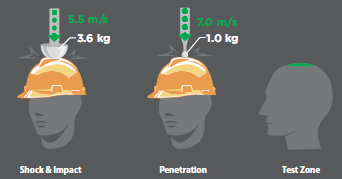

There are four specific performance requirements for Type I hard hats:

-

Flammability

No flame can be visible for five seconds after removing the test flame from the hard hat surface.

-

Force transmission

A single hard hat must not transmit force to the test head form exceeding 1,000 pounds of force. Conditioned hard hats (hot, cold, and ambient) shall be averaged, and the average cannot exceed 850 pounds of force to the test head form.

-

Apex penetration

The penetrator cannot make contact with the top of the head form.

-

Electrical classification (Class G, Class E, or Class C)

Class G and Class E hard hats must meet appropriate performance requirements:

- Class G to withstand 2,200 volts for one minute. Maximum leakage shall not exceed three milliamperes.

- Class E to withstand 20,000 volts for three minutes after impact. Maximum leakage shall not exceed nine milliamperes.

Class C hard hats are not tested for electrical insulation.

What Is a Type II Hard Hat?

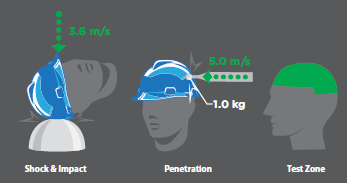

Type II hard hats based on ANSI and CSA standards are designed to reduce force as a result of an impact to the front, back, sides, AND top of the head.

In addition to the four performance requirements of a Type I hard hat, Type II performance contains three additional requirements:

-

Impact energy attenuation

Hard hat is dropped onto a spherical object at various angles around the hard hat, above a designated test line.

-

Off-center penetration

A penetrator is dropped vertically, and the hard hat is rotated at different angles above a designated test line. The penetrator cannot contact the head form.

-

Chinstrap retention (optional)

If a Type II hard hat is provided with a chin strap, chin strap must be tested for retention, must remain attached to the hard hat and must not stretch beyond one inch in length.

What Options are Available for Type I and Type II Hard Hats?

Solutions are available from MSA in both Type I and Type II hard hats

Type I options consist of V-Gard® Caps and Hats. This includes the V-Gard C1 ™ Hard Hat, which features ReflectIR™ Thermal Barrier technology to keep the inside of the hat up to 20°F cooler, and the V-Gard H1 Safety Helmet, which provides exceptional comfort and ease-of-use with a low-profile design.

Additional Type I solutions from MSA include: SmoothDome® and Thermalgard® Caps, Topgard® and Skullgard® Caps and Hats, Comfo-Cap® Hard Hats, and Nexus Climbing Helmets.

Type II options from MSA are Super V® Helmets, which feature a foam liner with integrated Fas-Trac® suspension and are slotted for use with MSA accessories.

Explore Type I and Type II Hard Hat Options

VIEW ALL PRODUCTSWhat makes EN397:2021 and EN12492:2012 approvals different?

When choosing an industrial hard hat, it’s important to understand how European standards for impact and penetration testing compare to those for US and Canada.

EN397 testing requirements for industrial hard hats are similar to those for ANSI and CSA Type I. It is focused on top impact ONLY for industrial use. MSA solutions with EN397 approval include V-Gard H1 NoVent and BiVent Safety Helmets.

EN12492 testing requirements provide a slightly larger top impact zone for mountaineering and climbing helmets; while EN12492 helmets provide additional top impact protection when compared to ANSI Type I hard hats, the standard is NOT equivalent to ANSI Type II, as it does not provide the same lateral protection that a Type II helmet provides. Prior to selecting a hard hat, be sure that it meets the appropriate protection requirements for your application. If lateral protection is required, the helmet MUST be certified as Type II. MSA ‘s solution for EN12492 requirements is the V-Gard H1 TriVent Safety Helmet.

What to Look for Before Using a Hard Hat?

Whether your job requires a Type I or Type II hard hat, it’s important to inspect your PPE prior to each use and throughout the day. Damage can occur without notice and compromise the protection capabilities. Any hard hat that’s been struck severely should be immediately removed from service and replaced. Even if it looks to be in good condition, hairline cracks that you can’t see will affect its integrity. Also, keep in mind that hard hat suspensions should be replaced on an annual basis.