You’ve done your homework and purchased the right gas detectors for your facility. Now it’s time to install them. But how do you decide where the sensors should be placed?

You already know gas sensor placement is tied to the particulars of your unique facility. But beyond that—because you must take so many variables into account—you have no hard-and-fast rules to follow. However, in this post we’re highlighting some best practices you can consider when you’re ready to install your gas detectors.

Learn about additional Do’s and Don’ts, download the MSA Guide to Sensor Selection and Placement

Download the PDFWe’ve identified three steps involved in the gas sensor installation process.

-

Observe

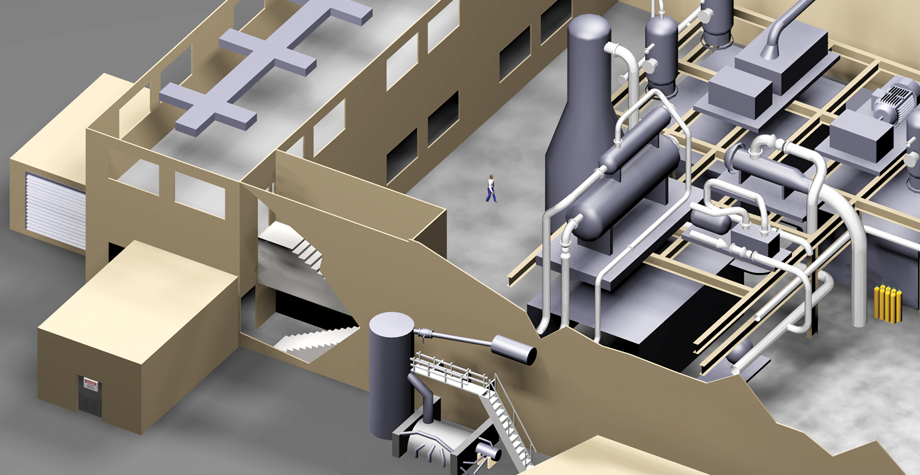

Perform a potential gas hazard assessment within your facility.

-

Document

Create drawings indicating all potential gas leak sites, as well as the severity of each site’s hazard potential.

The two main hazardous location categories are:

- Potential gas discharge points. These areas are locations where hazardous gases may be released, such as valve steam seals, gaskets, compression fittings, and expansion joints.

- Potential contact areas. These areas are locations where hazardous gases may endanger workers or damage equipment or property. Examples include populated areas; confined spaces; pits; stairwells; crawl spaces; shelters; and residential, business, and industrial environments located nearby.

-

Investigate

As gases do not always behave consistently, consider air flow conditions as well as potential gas pocket areas before placing sensors.

In general, when placing gas sensors, you should consider the following principles:

DO

- Place sensors close to the possible gas/leak source.

- Place sensors in areas where air currents are likely to produce the highest gas concentration, including areas where gas buildup is likely, such as corners or stopping points of gas-releasing moving devices.

- Factor in the monitored gas’s vapor density when compared to air. Sensors should be located near the floor for gases or vapors three or four times heavier than air. They should be installed near the ceiling or roof to detect lighter-than-air gases.

DON’T

- Don’t place sensors near entrances or fresh air vents during representative room sampling, as sample concentrations will be diluted by incoming air.

- Don’t mount the detector on a surface subject to vibration as it could damage the detector. Best practice is to anchor the detector to a wall or firm base rather than to a motor housing.

For additional DO’S and DON’TS, download the MSA Guide to Sensor Selection and Placement above.