The must-haves for a successful gas detection program go beyond compliance. Here are 10 key things to keep in mind when developing a gas detection program.

The main job of gas detectors is to help keep workers and worksites safe. The faster a sensor responds, the safer the workers and worksite will be. Sensors should accurately detect the presence of multiple gases simultaneously and notify you when they need to be replaced to prevent a lapse in protection and minimize downtime. Detectors should have a long sensor life and be built to last.

You need to trust your gas detectors to run effectively even on the toughest worksites. That’s why a detector’s Ingress Protection (IP) rating matters.

Look for equipment that has passed a 10-foot drop test and has an IP rating of IP68 for spray, dust and submersion. These tests are a great indication of durability, which has a direct impact on the total cost of ownership — an aspect that can’t be ignored when it comes to budgeting.

Battery capacity is key to a device’s ability to be on duty for long hours without charging. The longer the field life of the battery, the less maintenance and attention is needed from the safety department, so you spend more time monitoring and less time and money maintaining.

Automated test systems calibrate and bump-test gas detectors automatically. A test stand should be able to select a gas cylinder automatically and help you save gas volume.

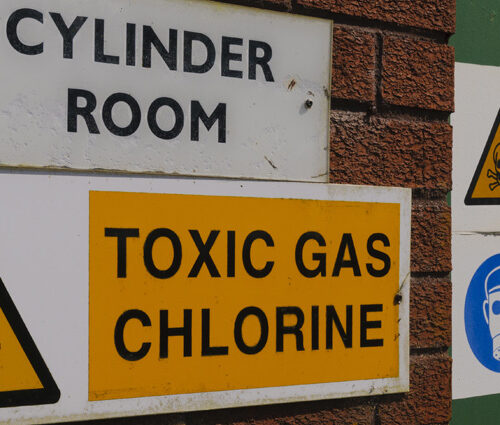

Whether used in confined spaces or in far-working locations like oil and gas platforms, the ideal product is designed to withstand the unique challenges of each environment and activity.

Gas detector suppliers that offer strong warranties stand behind their customer service and technical support. Substantial instrument and sensor warranties are a great indication of product quality and durability.

Software as a service consolidates all information from portables in one place. It should bring data from devices together in a user-friendly format so safety professionals can make the most of it. One of the most important benefits of software as a service is to allow safety managers to take a proactive approach to their portables by knowing in advance which devices need maintenance.

Your solution should alert you at the detector and remotely via computer or mobile device, simplifying system setup and connectivity. The latest gas detectors can share information, including any alarms triggered. This offers an unparalleled opportunity to gather and analyze data to streamline processes and improve safety.

You should not only look for durable gas detectors that feature the latest and greatest technology, seamless connectivity and ease of use, but also partner with a manufacturer that can back up its offerings with an excellent track record of safety and support.

With the MSA Connected Work Platform, you get the gas detection hardware and software that can help improve safety across workers, worksites, and workflows. Learn more.