Fall protection equipment needs to work. Right away. When manufacturers select quality materials that are right for the job, the equipment is more likely to work the way it’s supposed to, while offering an increased service life of the product.

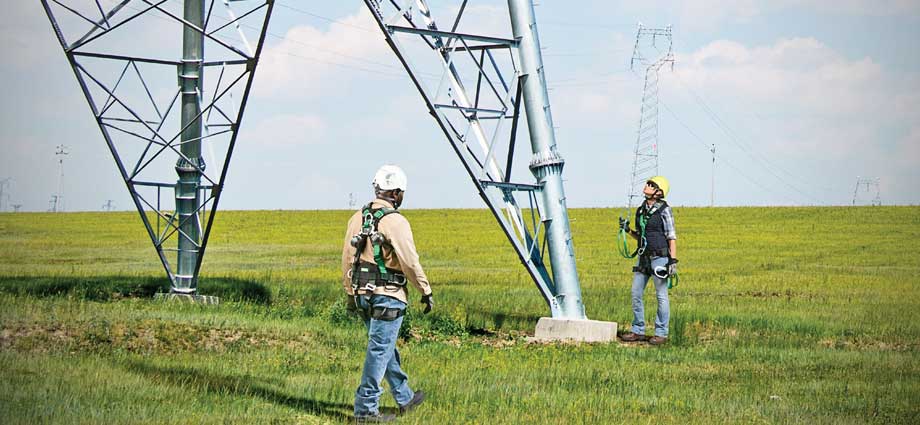

When you’re working at the mercy of Mother Nature, you’re going to want your equipment to have been designed to hold up against everything from the sun’s UV rays to ice and snow.

As part of product design, it’s important that a manufacturer considers what components are suitable for prolonged exposure to environmental elements. (For example, in dusty, wet, or corrosive conditions, marine-grade 316 stainless steel and bronze are materials that can and should be used in self-retracting devices.) Regardless of location, materials in personal protection equipment (PPE) need to be tailored to their environment.

How can you feel confident the materials you use are the right match for your worksite? Select equipment that was purpose-built and tested to perform in the conditions where you’ll find yourself working. More so, determine if your equipment is the right “fit” for the type of work you perform—so you’ll actually want to use it.

Materials and Innovation

You have plenty of options when it comes to PPE. The safest PPE in the world will do little, however, if workers refuse to wear it because it’s cumbersome, uncomfortable, or inconvenient. Enter radial energy absorption, an innovative technology new to the fall protection stage. Radial energy absorption is not a new technology, but its recent application in fall protection is new, essentially transforming energy absorption in PPE. The result? Precisely-engineered systems designed with safety in mind.

The radial energy absorber reduces the speed of a fall by causing friction between two rotating elements, meaning when a fall occurs—the user is brought to a gradual halt.

The benefit of this cost-effective solution is that it reduces the size of the energy absorber required within the product, offering a compact and comfortable solution to those wearing PPE at height.

How the Components Work Together

The stainless steel tolerance ring, which makes this whole process possible, is a pre-engineered integral energy absorber with pre-formed ridges around its circumference. These ridges create consistent friction and calibration. If a worker falls, the lifeline accelerates, leading the brake pawls to extend and lock against the chassis. Both the brake pawl holder and tolerance ring are stationary when locked, and the drum and bronze inner continue rotating under the tolerance ring’s resistance. Ultimately, the energy released is absorbed and reduces the output to less than the acceptable maximum arrest force of 6kN.

This energy absorption technology incorporated into the personal fall limiter (PFL) eliminates the need for an externally housed absorber, meaning that, in the event of a fall, you are protected by a product in the smallest-possible package. And small is a big deal. Bulky, cumbersome PPE makes doing your job harder and more time-consuming, but if you work without it, you put yourself in danger and risk safety violations. This product is easily transported, allowing workers to fit into smaller spaces and offering freedom of movement. It also weighs less, increasing comfort and making workers more likely to use their PPE—ultimately improving peace of mind for everyone on the job.

What’s on the Outside…

…protects what’s on the inside. And what’s on the inside is worth protecting. When you have technology as innovative as the radial energy absorber, you want to keep them protected from external contaminants by the best possible materials.

The casing is exceptionally durable, protecting the components inside, reducing wear and damage, and offering low cost of ownership. As such, these products are appropriate for workers at height in the majority of environments because the energy absorber is sealed from the elements and external contaminants.

Some of the PFLs containing radial energy absorption technology employ transparent, polycarbonate casing that gives workers a constant view of the technology inside. As such, visual inspection of the internal componentry is easy—and able to be completed onsite.

What to Look for in Fall Protection Equipment Materials

When working at a height, you never want to compromise quality when it comes to the materials in your PPE. Look for PPE made of materials that:

- Meet strict design scope criteria

- Function as intended to arrest a fall

- Resist corrosion and wear in even the harshest conditions

- Meet the strictest safety, function, durability, and usability criteria

Learn more about MSA’s unique radial energy absorption fall protection products here.