When most people hear the phrase enter a confined space, they think of wriggling into an attic crawl space or sliding behind the water heater in the basement. Uncomfortable and cramped, perhaps, but no big deal—or so they assume. Unfortunately, it’s easy to bring this casual attitude to the workplace, but industry professionals know that there’s much more to a confined space than meets the eye! Because many hazards—both seen and unseen—may await anyone working in a confined space, safety should always be the number one concern, especially on a job site. And that means understanding distinctions such as a non-permit work area (one with acceptable entry conditions) vs. a confined space vs. a permit-required confined space. To begin with, employers must identify all the confined spaces at every worksite. According to OSHA, to be considered a confined space an area must meet all of the following criteria, as follows:

OHSA 1910.146(b)

- Is large enough and so configured that an employee can bodily enter and perform assigned work.

- Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry.)

- Is not designed for continuous employee occupancy.

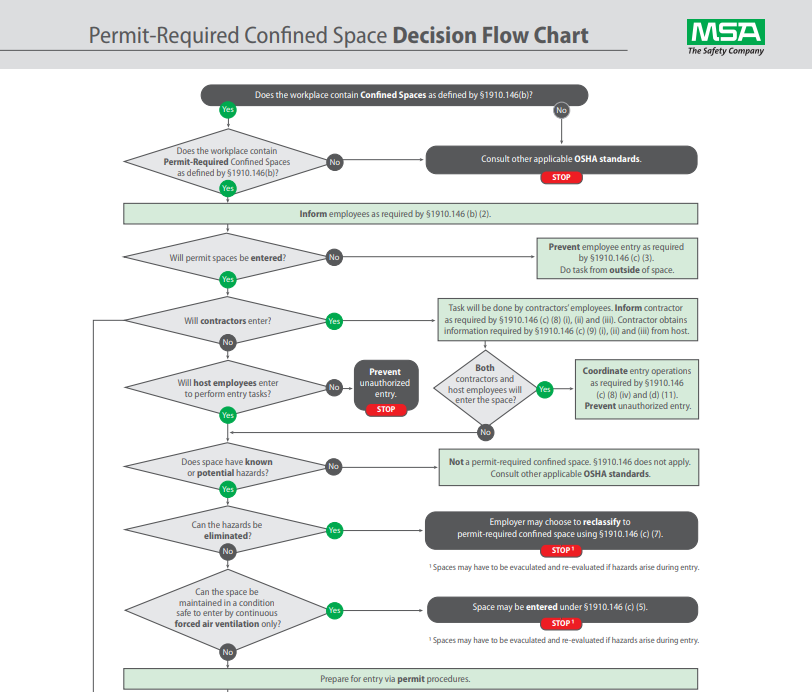

Furthermore, an employer must evaluate each confined space with regard to (a) hazardous atmosphere; (b) engulfment; (c) entrapment or asphyxiation; and/or (d) other recognized serious safety or health hazards. If one or more of these indicators risk a worker’s health or safety, the area qualifies as a permit-required confined space. For help with your specific situation, click here for a decision flow chart. Once a permit-required confined space has been identified, OSHA 1910.146 and (Construction) OSHA 1926.1200 outline the required safety practices and procedures to be used in connection with tasks performed in the area. These regulations have been designed to leave as little as possible to chance so that emergencies can be avoided, or—if a crisis does occur—workers can either self-rescue or be rescued safely. This may sound straightforward, but working out the details of a permit-required confined space operation can be challenging. For instance, although sometimes overlooked, solid management support can mean the difference between success and failure. Additionally, factors such as controlling and/or eliminating hazards, documentation, and the team’s knowledge and skillset must be considered in order to enter, work in—and get out of—a confined space safely. Lastly, it’s important to note that this standard relates to OSHA’s 29 CFR 1910.146 for confined space in general industry. Other confined space standards exist for additional industries and it’s important to consult the appropriate standards for your industry. We’ve included links to several confined space regulations as listed by OSHA OSHA Confined Space General Industry:

OSHA Confined Space Construction:

- https://www.osha.gov/confinedspaces/index.html

- https://www.osha.gov/confinedspaces/1926_subpart_aa.pdf

If you’d like a closer look at these key principles and more, click to watch the Ins and Outs of Confined Spaces online webinar.