You’re an industrial safety professional. You encourage using the right PPE. You know the value of protecting workers from injury — head to toe.

Think about this for a minute: the head is about one-seventh of a body’s total height, but it’s the nerve center for everything done on the job site. Your eyes, your ears, your nose… almost everything you use for sensory input resides there.

But, your head also houses the most important organ in your body: the brain. If damaged, nothing else functions properly. Head protection helps to safeguard this vital organ that’s so important, both on the job and off.

That means choosing the right hard hat for your application is critical.

There are other important hard hat facts on selection, care, and replacement timeline you must know. To get the rest of the story, download our free special report here.

Download the WhitepaperTypes of Hard Hats

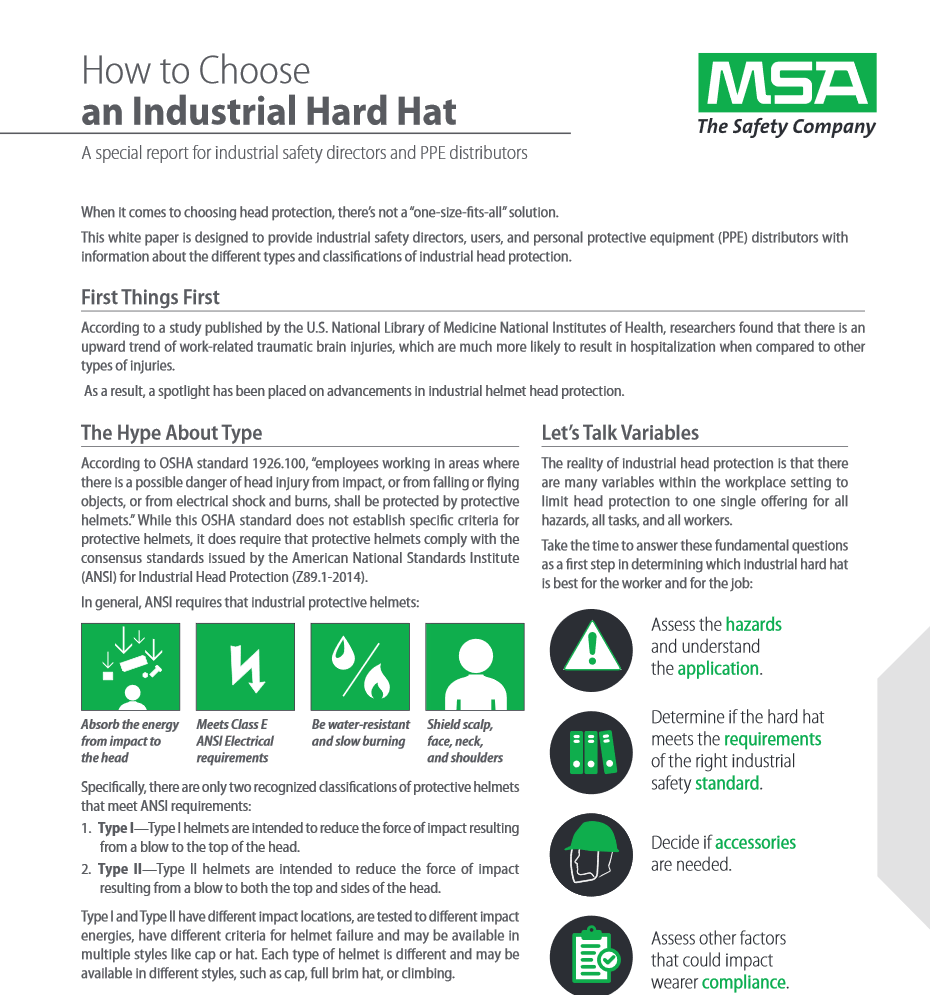

When I say “types,” I’m not talking about cap, full brim, or climbing models. Those are styles. Type refers to a standards designation. The current ANSI consensus standard for hard hats is Z891.1-2014.

A Type I hard hat is certified to reduce the impact of blows to the crown or top of the head. If tools, small parts, or other items are dropped from a height (or if you raise up under an obstruction and bang your head), you’re protected.

A Type II hard hat cushions the impact from top of the head blows, but also protects the worker from lateral impact. This is a requirement when working around moving equipment or materials where a side blow is possible.

In Canada, the hard hat standard is CSA Z94.1-15, updated on March 1, 2016. While similar to the ANSI standard, there are some variances in the testing requirements. CSA Type 1 is similar to Type I in the US, and CSA Type 2 resembles the ANSI Type II.

While these two standards are similar, a hard hat certified by one organization doesn’t automatically qualify it for the other. The testing procedures used are specific to each standard.

For example, a hard hat certified by ANSI Z891.1-2014 must also pass the CSA Z94.1-15 standard if it is to be sold to the Canadian market. So, don’t assume the hard hat you purchased in one location or country will be in compliance everywhere you work. Make sure it’s certified and labeled for your location.

Understanding a hard hat’s “Class”

A hard hat’s Class designation is different from its Type. While Type represents impact protection, Class refers to electrical protection. In the past, the electrical class designations were A, B, and C, with A being the highest hazard rating.

However, the Class labels are now E, G, and C. As you’ll see, this labeling system is more intuitive when choosing the right hard hat. The electrical ratings are:

- Class E (electrical, non-conductive) – Intended to reduce the danger of contact with higher voltage conductors, with hard hat test samples proof-tested at 20,000 volts (phase to ground).

- Class G (general, non-conductive) – Intended to reduce the danger of contact with low voltage conductors. Test samples are proof-tested at 2,200 volts (phase to ground).

- Class C (conductive, no electrical rating) – Not intended to protect against electrical hazards and, therefore, are not tested for it.

Electrical workers are more at risk from high voltage electrical hazards and should use Class E hard hats.

General construction workers, who may come in contact with low voltage hazards should use a Class G hard hat, at minimum.

Workers proven to be without the possibility of electrical hazard contact can use a potentially conductive Class C hard hat.

Some final hard hat tips

A hard hat is designed to protect from impacts that could damage the brain. So, take its upkeep seriously. Sunlight can affect many hard hat materials, so make sure your hard hat is stored away from it. That means it really shouldn’t be left on a truck’s dashboard or hanging from a hook on the back windshield.

Prolonged or even incidental contact with some chemicals and harsh detergents can deteriorate the shell’s materials. It should never be cleaned with gasoline, paint thinner, or any petroleum-based liquid. Mild soap and water are safe to use. If tar or other sticky materials can’t be removed with soap and water, it’s better to replace the hard hat and not risk worker safety.

Inspect hard hats regularly throughout the day. Damage can occur without notice and compromise protection. Of course, any hard hat that’s been struck severely should be immediately removed from service and replaced. Even if it looks OK, hairline cracks that you can’t see will affect its integrity.

And always remember this. Your head may only be a 15% of your body height…but, protecting it deserves 100% of your attention. Work safely!