Your building’s mechanical equipment room is the hub of its HVAC system. But the equipment in these rooms has the potential to leak toxic gases—including costly and environmentally harmful refrigerant gas. At high concentrations, these gases can displace oxygen, endangering facility personnel.

Fundamentals

Let’s review the three primary reasons to monitor equipment rooms for refrigerant gas leaks: worker safety, economic considerations, and environmental concerns.

1. The first, and most important, objective is to provide men and women with a safe work environment.

Refrigerants are toxic and considered an asphyxiate at high concentrations. ASHRAE 15—the standard governing refrigerant leak detection in machinery rooms—deals with personnel safety. It states that:

- Each machinery room shall contain a detector located where a refrigerant leak would concentrate.

- The detector shall trigger an audible and visual alarm both inside and outside the mechanical room and activate mechanical ventilation.

2. Economic factors also come into play.

The loss of refrigerant plus the recovery process plus the evacuation of the affected area equals lost productivity and higher operating costs. The most cost-effective refrigerant leak monitor uses sample-draw technology, in which a central panel pulls a sample drawn from various lengths through a sensor. Mounted inside or outside the mechanical room, the monitor uses either flexible tubing such as polyurethane or hard tubing such as stainless steel or copper.

3. Lastly, several regulatory bodies drive requirements concerning unauthorized greenhouse gas emissions.

Expect this trend to grow as global warming continues.

Real-World Recommendations

Since refrigerant is heavier than air, it tends to pool towards the ground; therefore, ensure that sampling lines are not placed too high to detect leaks. Best practice prescribes locating sample lines towards the barrel of the chiller on adjacent sides for complete coverage. Additionally, consider positioning a sampling line in recently serviced or known problematic areas.

A sensitive leak monitor is one of the best ways to help prevent a minor incident from becoming a crisis. The monitor should:

- Activate exhaust ventilation systems.

- Interface with a Building Management System (BMS) using either digital or analog communication.

- Notify facility personnel of a hazardous situation.

Further Insight

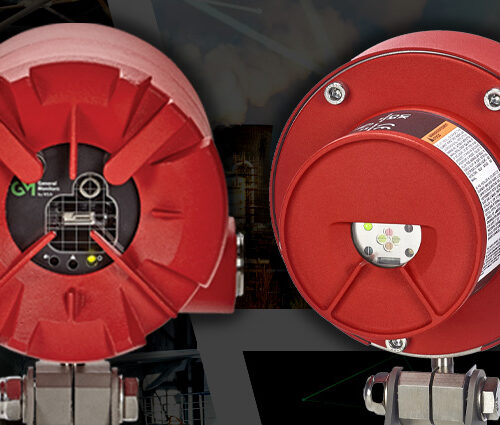

If you’d like to learn more, a new on-demand webinar details how MSA Safety’s Chillgard® 5000 Refrigerant Monitor can help mitigate harmful and costly refrigerant leaks.

- See how the earliest level of detection keeps leaks under control.

- Discover how predictive maintenance results in worry-free operation.

- Understand how a modular, scalable design allows for low cost of ownership.