Dirty, hazardous jobs are all in a day’s work for wastewater treatment plants. But just because odors and hazards are commonplace, doesn’t mean safety and facilities managers get a pass on prioritizing worker safety.

Of course, safety must be taken seriously by limiting worker exposure to hydrogen sulfide (H2S), methane (CH4), carbon monoxide (CO), and other hazardous gases.

But is your facility doing everything it can to ensure compliance with NFPA Code 820? Specifically, is it effectively monitoring wet wells for potentially lethal (and often invisible) combustible gases?

What are wet wells?

Pump stations are home to wet wells, which are large, open holding tanks in which wastewater is pumped from municipal sewer lines and held prior to treatment. It is here that heavier solids are left to sink to the bottom while lighter solids float to the top for removal before the remaining wastewater is pumped for secondary treatment.

Naturally occurring combustible and toxic gases are ever present in varying quantities during this process. Though typically invisible, these gases can emit a pungent or “rotten egg” odor that’s often deceiving in terms of their potentially lethal nature for both combustibility and toxicity.

Combustible and toxic gas detectors can be used to alert system operators whenever the intensity of these noxious gases intensify to the point of being a serious fire hazard or respiratory threat to workers.

Additionally, the wet wells environment also holds the potential to create oxygen (O2) deficiency conditions, especially in confined spaces; yet another reason to employ fixed gas detectors within these areas.

Why NFPA Code 820 Matters

NFPA Code 820 is a standard for fire protection in wastewater treatment and collection facilities, including pumping stations, chemical- and sludge-handling facilities, and ancillary structures. The standard is designed to protect life, property, operations, and the environment from fire and explosion hazards.

At a minimum, NFPA 820 requirements include:1

- Reducing or eliminating the effects of a fire or explosion

- Maintaining the structural integrity

- Controlling flame spread and smoke generation

- Preventing the release of toxic products of combustion

- Ensuring serviceability and operation of the facility

The standard specifically calls out three separate process areas related to combustible gases:

- Collection Areas

- Liquid Streams

- Solids Treatment

Wet well monitoring falls under the Liquid Streams process area of the standard. In general, the standard for this process area requires a variety of fire protection materials, including a combustible gas detection (CGD) system. Please see the current edition of NFPA 820 for the exact details for combustible gas detection monitoring, including the Liquid Streams process area of the standard.

Non-Compliance Issues

System operators and safety managers may want to conduct an audit of their treatment plants and pump stations in order to identify potential areas of non-compliance, such as these:

- Equipment not rated for use in a hazardous area

- Lack of explosion-proof equipment rated for hazardous atmosphere

- Inadequate ventilation and ventilation monitoring

- Lack of sealing fittings that prevent migration of gases and spread of flame

- No combustible gas detection (CGD) products

Maintaining Compliance with a Combustible Gas Detection System

NFPA 820 is explicit in its recommendation for CGD sensors in pumping stations and other areas of a wastewater treatment facility, including wet wells, and defines CGD as follows:

3.3.12 Combustible Gas Detector. A gas detector used to detect the presence of flammable vapors and gases and to warn when concentrations in air approach the explosive range.

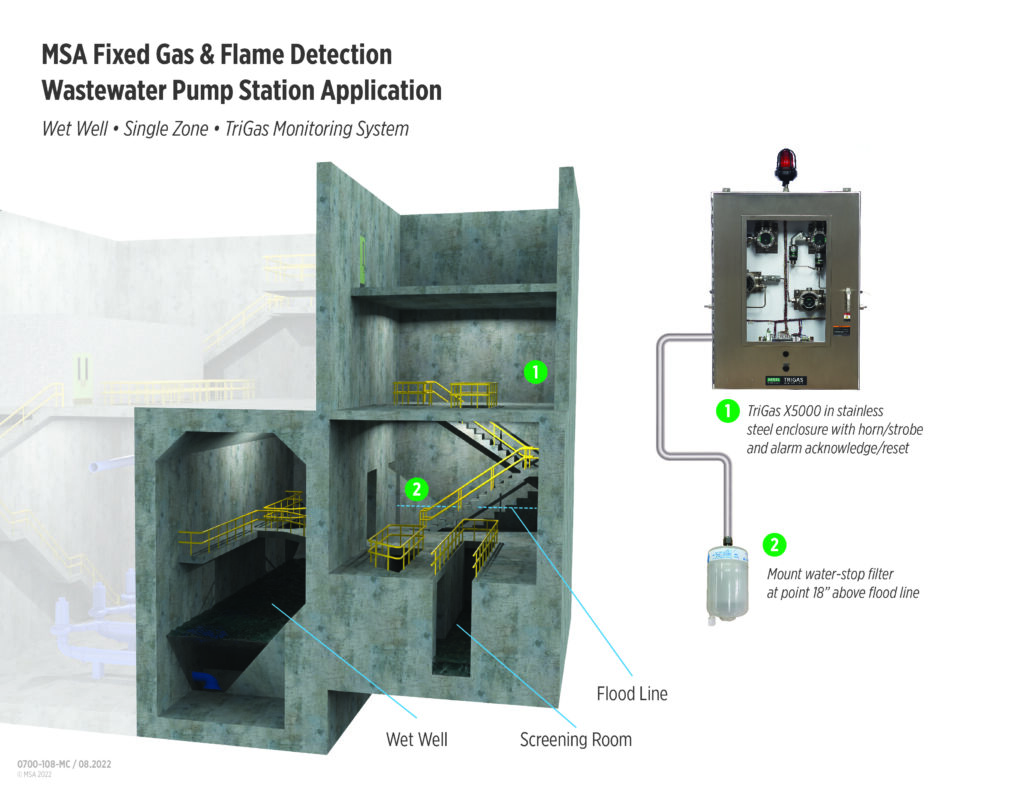

To better protect pumping stations and wet well areas against hazards while helping ensure NFPA 820 compliance, plant operators will want to consider installing an integrated CGD product like the MSA TriGas Monitoring System.

The TriGas Monitoring System enables operators to monitor and detect oxygen, hydrogen sulfide, and combustible gases (methane or petroleum vapors). Plus, it’s ideal for harsh, high-moisture environments and areas subject to flooding, such as wet wells. This system is available in a wall-mounted NEMA 4X fiberglass or stainless-steel enclosure to include combustibles, H2S and O2 gas monitors, sample pump and end-line filter, power supply and alarming system to include buzzer and strobe light.

Additional Applications

When it comes to NFPA Code 820 compliance it is absolutely critical to monitor wastewater treatment plant wells for combustible gases. Failing to do so could result in a tragic accident or catastrophic consequences, including loss of life.

“MSA is a safety leader in gas detection,” says Tim Wolk, MSA Safety’s Municipal Market Sales Manager. “We, along with our many suppliers and partners offer combustible and toxic gas monitoring systems that meet or exceed the requirements of NFPA 820. Chances are, if you have a gas detection problem, we can solve it.”

To learn more about keeping your employees, equipment, and facilities safe by staying NFPA 820 compliant, download Monitoring Wet Wells for Combustible and Toxic Gases to Meet NFPA Code 820. This free article also includes detailed information on the various gases and their potential effects on worker well-being.

Sources:

[1] Wolk, Tim. NFPA 820 Guidelines for Combustible Gas Detection with MSA.” YouTube, uploaded by Dave Heiner Associates, Inc, 10 December 2020, https://youtu.be/_FYqt4U-u7Q.