Matt DeLorenzo, business director of Software Applications at MSA Safety, explains how technology is improving safety via a transformation of the way safety devices are managed, and how operator safety is monitored while at work.

Improvements in safety, both in practice and equipment, have essentially always stemmed from one thing: the availability of good information. In the past, that learning was often observational, based on talking to individuals, or derived from scrutiny or analysis of historic written and pictorial hard copy records.

Today, thanks to the advances in digital data capture and recording by sensors and devices, information is a commodity that is not in short supply. The seamless connectivity driving the Internet of Things is already touching workplaces globally. The latest flame and gas detection devices typically offer the ability to log performance and environmental data. But translating that into tangible learnings is not always easy.

The Big Data Challenge

Processing and intelligently analyzing large data volumes, particularly when gathered from “real-time” streams, is now one of the safety industry’s biggest challenges. For data to be meaningful, it has to provide real insight. That starts with being able to automatically detect, highlight, interrogate and share those events that are most relevant and significant to the operation of a device, or the ability of an worker to complete his or her work safely.

Recent advancements of AI-enabled automated reporting tools allow safety managers to look beyond just managing safety compliance towards changing how workplace safety really works. The ability to analyze and review historical logged data and extract actionable information to reduce risk and improve workplace safety is transformative.

Insight to Plan Ahead

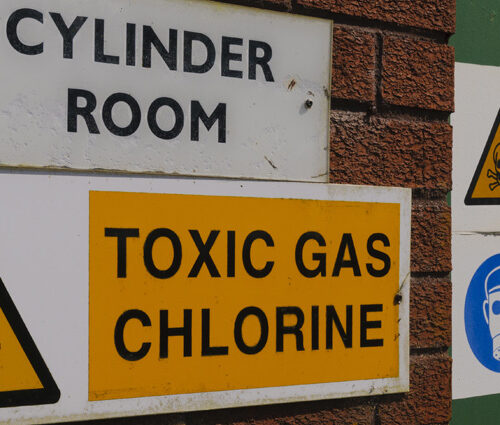

Data analysis and proactive maintenance can help to streamline the day-to-day monitoring of equipment, eliminate potential risk of human error, and free up time for safety managers to concentrate on driving meaningful behavioral safety improvements. Automatic notifications, for instance, can highlight when equipment components are likely to require maintenance or replacement, allowing pre-emptive action. Worker safety is improved, and costly downtime or operational delays minimized. Gas detectors, for example, rely on sensors that have a finite lifetime. Analysis of usage data can automatically highlight that a sensor’s end-of-life is approaching, and a replacement should be ordered. Similarly, correct detector operation is verified by using bottled gas testers before use. If the gas runs out, detectors cannot be tested. Safety protocol dictates that workers cannot work. Yet by providing automated alerts about remaining capacity, spare cylinders can be ordered earlier. The ability to instantly track equipment and its location digitally, without resorting to lists on clipboards, also offers significant savings in time and loss of assets.

An Essential Record

Historically, daily data would remain on each device and be routinely overwritten, unless an event prompted a sporadic download, or a written report. Today, maintaining historic central archives of detection device data – sometimes spanning decades – provides companies with an invaluable record. Any exposure incidents or toxic breaches can be thoroughly analyzed and documented.

For workers, the advent of real-time monitoring during operations via live feeds is revolutionizing safety. Data streaming can provide safety controllers and colleagues with situational awareness, physical status and the ability for workers to issue individual or team evacuation alarms and even mobilize first responders should a situation arise.

Engineering Value, Not Innovation, First

Developing next-generation safety technology is of course hugely dependent on innovation, but truly listening to and understanding customer needs and feedback to engineer the necessary hardware and software functionality is of equal importance. It’s listening carefully to customers’ feedback and applying those learnings in an innovative way that produces next-generation safety technology.

Adoption will stand or fall on the ability of solutions to add value to multiple stakeholders without completely changing the way safety management and procedures work. Seamless integration and easy, intuitive operation only comes from extended testing by everyone involved – from safety managers to supervisors to workers. Of course, innovation is meaningless unless the underlying outcome offers a real-world, practical benefit.

Expect the Best

There is no doubt that technological advances are having huge impact on the world as a whole. All things considered, the health and safety industry should embrace the opportunities new technologies provide to keep workers connected, thus providing an additional layer of safety through technology.

MSA encourages the industry to ‘expect more’ from gas detection programs. That’s why the Connected Work Platform – driven by the new ALTAIR io™ 4 Gas Detection Wearable – was developed. With the ALTAIR io 4 and MSA’s Grid cloud-based software, you can help improve visibility and safety across your workers, worksites, and workflows.

Learn more about the Connected Work Platform.