Refrigerant gas detection has been crucial in the marketplace for many years. It helps ensure safety of occupants and workers, aids in the protection of the environment, and supports regulatory compliance. As the refrigeration market tightens its industry regulations with legislations like the AIM Act and guidance put forth by California Air Resources Board (CARB), refrigerant gas detection is becoming a necessity. There are two different types of leak detection systems to discuss – diffusion systems which can help facilities maintain safety compliance for people and aspirated systems that have advance sensing technology that can help reduce harmful gases and refrigerants.

Key differences between systems:

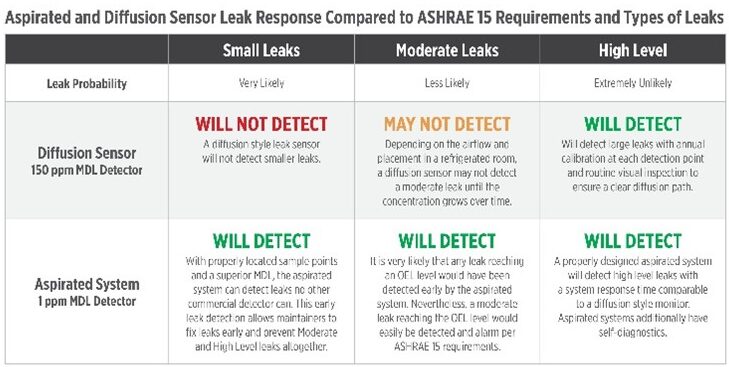

Diffusion-based detectors rely on natural movement of gas molecules through an occupied space without active air sampling to detect leaks. Gas molecules diffuse through the air and reach the detection sensors positioned strategically within the leak path of the monitored area. Diffusion systems do not require a central detection unit or network of pipes for air sampling

Aspirated use a pump to actively draw air or gas samples into a detection chamber where they are analyzed for the presence of gas using a centralized sensor module. The continuous air sampling allows for precise and realtime detection of gas leaks, making aspirated systems more sensitive to small leaks.

Diffusion devices generally take longer to reach a measurable gas concentration as they rely on the natural air movement to carry gas molecules to detection sensors without active air sampling.

Aspirated systems offer faster detection since they actively draw air from the monitored area and can be set for continuously sampling, allowing for rapid detection of gas leaks within minutes of occurrence

Diffusion leak detectors tend to be less expensive since they require simpler components.

Aspirated systems come at a higher price point due to additional components such as pumps and tubing to actively draw the gas samples. They have a higher cost for initial hardware and installation, but do not need regular calibration and servicing. This lowers the total cost of ownership for aspirated systems, which offer earlier and lower level gas detection capabilities than diffusion. Although aspirated system may be pricier than diffusion, the potential cost savings can be significant. If you can catch a leak early with an aspirated system, a facility can avoid downtime of their equipment because of lost refrigerant and may not need to recharge with as much expensive refrigerant into the system.

Probably the biggest benefit of aspirated systems is the crucial role they play in staying compliant with new refrigeration legislation, particularly legislation aimed at reducing emissions of greenhouse gases and ozone- depleting substances. Here are some ways aspirated systems are providing solutions to refrigerant management needs in the field:

Emission Reduction Requirements

- Many countries and regions have implemented regulations that set limits on allowable leakage rates from HVACR systems. Aspirated leak detection systems help facilities comply with these requirements by continuously monitoring for leaks and providing early detection, thus minimizing emissions.

Environmental Impact

- Aspirated systems are designed to detect leaks promptly, allowing facility managers to immediately mitigate leaks. This proactive approach helps prevent the release of refrigerants into the atmosphere, which can contribute to global warming and ozone depletion.

Regulatory Compliance

- New refrigerant legislation often mandates the use of leak detection systems within certain types of facilities. Aspirated systems are often favored for their sensitivity and ability to detect leaks with faster sampling times, which can ensure compliance with regulatory requirements.

Monitoring and Reporting

- Aspirated systems provide continuous monitoring of refrigerant levels utilizing cloud-based services and refrigerant tracking and compliance software that can generate data and reports that document compliance with regulatory standards.

Transition to Low GWP-Refrigerants

- Some refrigerant legislation mandates the phase-out of high-GWP refrigerants in favor of low-GWP alternatives to mitigate climate change. Aspirated systems support this transition by helping facilities maintain the integrity of their refrigeration systems and minimize leakage of both traditional and new refrigerants.

MSA can help you determine the appropriate leak detection solution for your facility’s needs. Whether you are looking for a practical and cost-effective diffusion systems to help maintain certain safety standards, or the advanced capabilities of an aspirated system with real-time monitoring and helping to keep you complaint with new safety legislations, we have solutions to fit every need.