The penalty fees for OSHA violations have been amended annually since enactment of the Federal Civil Penalties Inflation Adjustment Act Improvements Act of 2015, as the United States Department of Labor has explained.¹

The annual increases are based on the national consumer cost of living computations for the previous year. This is designed to avoid the penalty increases appearing arbitrary.

When the U.S. Department of Labor released the increase for 2022 – that all penalties are multiplied by 1.06222, which is the cost-of-living adjustment multiplier for 2022 based on the Consumer Price Index for All Urban Consumers for October 2021 – the announcement/memorandum explained that:

“The cost-of-living adjustment multiplier for 2022, based on the Consumer Price Index for All Urban Consumers for October 2021 (not seasonally adjusted), is 1.06222. To compute the 2022 annual adjustment, the Department multiplied the most recent penalty amount for each applicable penalty by the multiplier, 1.06222, and rounded to the nearest dollar. The adjustment factor of 1.06222 is consistent across the minimum and maximum penalties set forth in the Occupational Safety and Health Act and the FOM.”

It is too early to know what the multiplier will be for 2023 but this index has shown increases larger than 1.06 % so far in 2022. For example, the June 2022 version of this index increased 1.3% seasonally adjusted and its “all items index increased 9.1 percent [over the previous 12 months] before seasonal adjustment.”²

The Minimums and Maximums for 2022

Based on that multiplier, OSHA listed penalty amounts and ranges for 2022 in memorandum tables that are available in the OSHA Information Systems. OSHA uses 2 tables that characterize violations in different ways: (1) the penalty maximum and minimum range is based on OSHA’s assessment of the type of violation or its severity and (2) the penalty amount within a range is based on OSHA’s assessment of the gravity of the penalty, also known as GBP or “Gravity Based Penalty.”

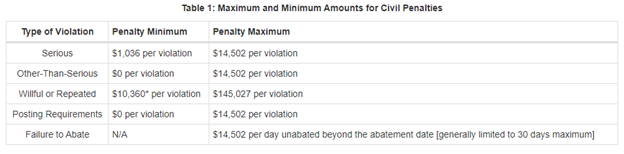

First, Table 1 below shows the penalty ranges based on type of violation or severity for civil penalties in 2022.

It also contains the following note under the table: For a repeated other-than-serious violation that otherwise would have no initial penalty, a GBP penalty of $414 shall be proposed for the first repeated violation, $1,036 for the second repeated violation, and $2,072 for a third repetition.

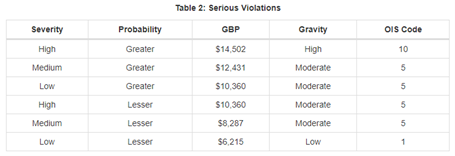

Second, OSHA publishes GBP tables for each type of violation that is listed in Table 1. For example, Table 2 indicates the GBP within the range of serious violations.

The GBP for serious violations is calculated by taking the severity of the violation and adding it to OSHA’s assessment of the probability of injury, death, or damage. In sum, a high gravity violation has a GBP of $14,502. For a moderate gravity violation, the GBP ranges from $8,287 to $12,431, and a low gravity violation has a GBP of $6,215.

One resource with additional information – including the criteria and guidance for how OSHA assesses violations and determines fees – is OSHA’s Field Operations Manual (“FOM”).³ This manual contains OSHA’s internal “information and guidance” to its own offices regarding its “policy and procedures for implementing inspections, issuing citations proposing penalties.”

The FOM contains additional guidelines for determining civil penalties. According to OSHA, these penalties are intended as more of a deterrent to, rather than a punishment for violations.

So, what are the most common OSHA violations found in the workplace?

OSHA’s Top 10 Most Frequently Cited Workplace Violations for Fiscal 2021

Last fall, OSHA announced a preliminary report of its Top 10 most frequently cited violations for fiscal year 2021.4 Once again, for the 11th year in a row, fall protection tops the list. Here are the top violations, in order of frequency:

- Fall Protection – General Requirements (1926.501): 5,295 violations

- Respiratory Protection (1910.134): 2,527 violations

- Ladders (1926.1053): 2,026 violations

- Scaffolding (1926.451): 1,948 violations

- Hazard Communication (1910.1200): 1,947 violations

- Lockout/Tagout (1910.147): 1,698 violations

- Fall Protection – Training Requirements (1926.503): 1,666 violations

- Personal Protective and Lifesaving Equipment – Eye and Face Protection (1926.102): 1,452 violations

- Powered Industrial Trucks (1910.178): 1,420 violations

- Machine Guarding (1910.212): 1,113 violations

The Keys to Compliance are Education, Prevention, and Protection

A driving force behind any safety program should be the health and well-being of employees. Some key factors in those programs are: education, prevention, and protection, which can be the subjects of multi-day trainings and seminars. Here are a couple reminders.

- Education and training are so important that OSHA devotes quite a few of its online resources to those topics. You can find information concerning the OSHA Training Standards Policy Statement here. OSHA also provides assistance to employers in developing their programs and training.

- Prevention can be accomplished multiple ways, and often involves safety walkthroughs to identify potential hazards and develop plans of action to mitigate them. Additionally, some equipment can monitor certain situations that could become dangerous. For example, portable and wearable gas detectors and other equipment such as flame detectors should be a part of certain safety programs, to help protect workers and worksites.

- Appropriate personal protective equipment (PPE) for the circumstance and setting is also critical to safety and compliance.

PPE Options for Top OSHA Violations

The number one listed OSHA violation for the past 11 years is fall protection. Supplying workers with personal fall protection equipment for their circumstances and setting, such as harnesses, self-retracting lanyards (SRLs), and horizontal lifelines is crucial when team members work at heights. Keep in mind that lifelines used on areas like rooftops require a specifically designed construction for working near edges.

Coming in at number two on OSHA’s list is respiratory protection. Self-contained breathing apparatus (SCBA) and full or half-mask elastomeric respirators provide protection from certain inhalation hazards, such as fumes, mists and gases.

Eye and face protection ranked eighth on the Top 10 list. Head protection, hearing protection, and eye protection are often accomplished together as a package or assembly, with hard hats as the supporting piece for the others. For crew members that work in direct sunlight with potentially high temperatures, hard hats that feature thermal barrier technology can help keep the inside of the hard hat cooler and help prevent heat-related illnesses.

To make sure you’re staying up-to-date with these and other OSHA guidelines, standards updates, and resources and tips about PPE, safety, and compliance, subscribe to the MSA blog here.

Sources:

[1] https://www.osha.gov/memos/2022-01-13/2022-annual-adjustments-osha-civil-penalties

[2] https://www.bls.gov/news.release/cpi.nr0.htm

[3] https://www.osha.gov/enforcement/directives/cpl-02-00-164

[4] https://www.nsc.org/newsroom/osha-reveals-top-10-safety-violations-for-fy-21-at