Safety professionals are used to leading worker safety initiatives across worksites that can be separated by tens, hundreds, and even thousands of miles. The COVID-19 pandemic, however, presented new safety management challenges including safety professionals themselves being asked to work from home, while their essential worker colleagues continue to report to the worksite.

Although the physical location of “the office” might have changed, expectations around safety goals and outcomes have not; in fact, in some cases, the level of urgency and scrutiny has increased. More than ever, safety professionals are feeling the need to have a full view of their safety programs and be in control, even when away from the office.

The scenario becomes even more sensitive when it comes to gas detection safety. A study published by the United Nations in 2019 estimates that one worker dies every 30 seconds from toxic exposure in their workplace.1 Because incidents of exposure are grossly under-reported in some contexts and countries, this figure is an underestimation.1 Just in the United States, accordingly to the Department of Labor, between 2011 and 2017, 116 workers died in a single inhalation of carbon monoxide and another 46 died in a single inhalation of hydrogen sulfide.2

Gas detection safety brings safety professionals a number of concerns and challenges:

- Whether the required portable gas detector or area monitor is…

- properly maintained?

- compliant and ready to use?

- accounted for?

- Even once workers are outfitted with the appropriate portable gas detector, how to know…

- the equipment is being worn or used correctly?

- safety protocols and standard operating procedures are being followed?

- In those scenarios or in the event of an incident, how to…

- review related records or documentation?

To manage these areas of concern effectively, you need visibility despite where you happen to be sitting this week.

Fortunately, there are tools and services available to help you manage your fleet of portables.

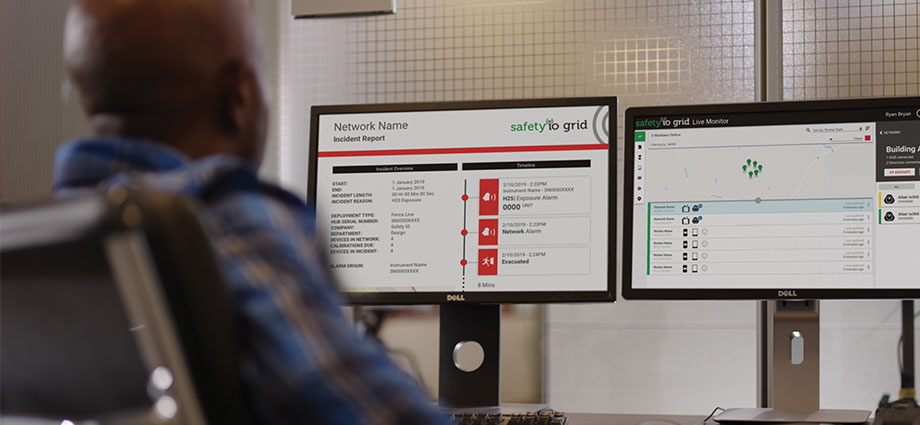

With the assistance of cloud-based software, modern gas detectors and area monitors can share their readings via a variety of connectivity options, making data quickly available for immediate review and easy to access for historical reasons. A responder can react instantly and accordingly when an alarm sounds, even when away from the office. Easier access to data means faster, more appropriate reactions and better decisions – leading to better safety outcomes.

Every day, our customers experience the benefits of a connected safety program when they see how MSA ALTAIR io™ 4 Gas Detection Wearable and Grid software can help them have control of their gas detection program, uncover safety training opportunities, and drive individual accountability even when working remotely.

Watch this on-demand demo to see how the ALTAIR io 4 device and Grid software work together to help improve safety.