It’s usually gratifying to be associated with a Top Ten List—for example, living in one of the Top Ten Places to Retire or getting a job at one of your city’s Top Ten Workplaces. These are distinctions you brag about because they emphasize satisfaction and success.

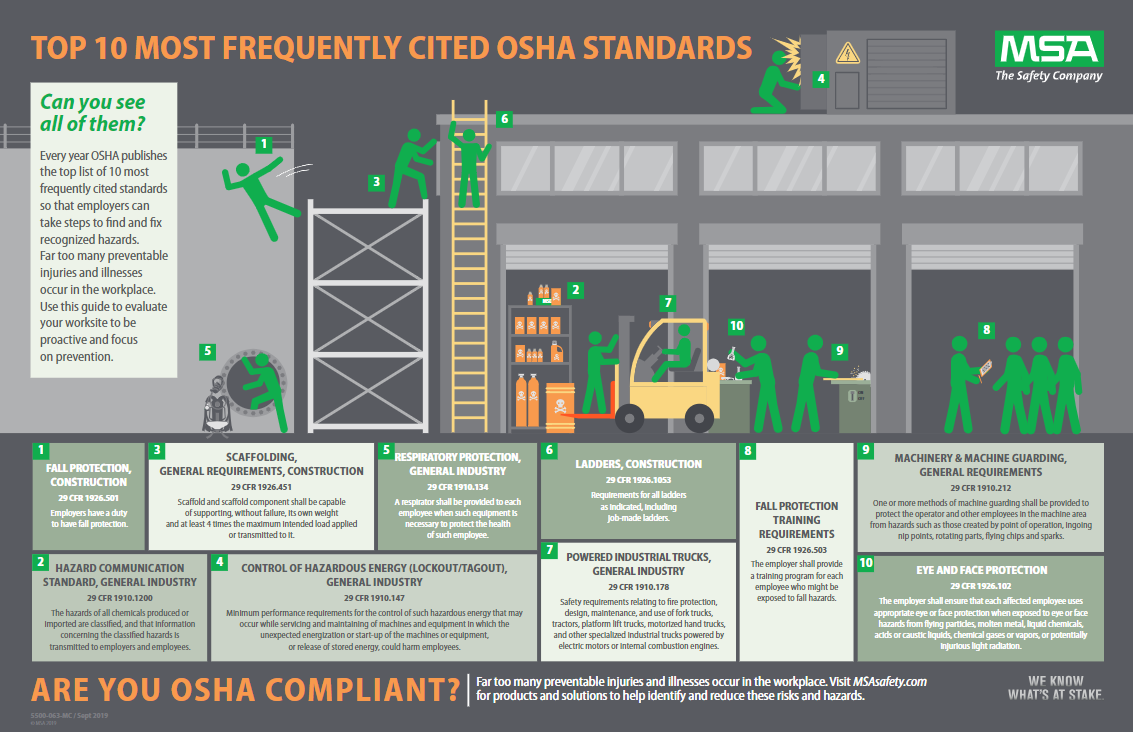

But, unfortunately, there are some Top Ten lists you don’t want anything to do with, and one such list is OSHA’s annual Top Ten Most Frequently Cited Standards List. Every year, workers are exposed to dangerous worksite conditions that likely could have been significantly minimized through compliance with OSHA standards.

So why should you check out OSHA’s “bad news” list every year? Because you can learn from others’ mistakes. That’s exactly why OSHA publishes its Top Ten List: so that you “can take steps to find and fix recognized hazards addressed in these and other standards before OSHA shows up.”[1]

Download our Top 10 infographic to share with your team!

Announced at the latest National Safety Council Congress and Expo, OSHA’s 2019 Top Ten List remained mostly the same as that of 2018—only #4 and #5 flipped positions.[2]

What you don’t know CAN hurt you

Last year this blog focused on the most violated OSHA standard, 29 CFR 1926.501, Fall Protection – General Requirements. This year we’ll look at 29 CFR 1910.1200, the Hazard Communication Standard (HCS), which has the dubious honor of being ranked as the second most violated standard. This standard concerns general industry chemical safety and states that “information about the identities and hazards of the chemicals must be available and understandable to workers.”[3]

Recently aligned with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), the HCS regulates chemical hazard classification, labeling, safety data sheets (SDSs), and worker training. Employers must address issues such as:

- Have we identified every hazardous chemical to which our workers may be exposed?

- Have we labeled these chemicals correctly?

- Do our workers completely understand the dangers of these chemicals, and is specific information readily available to them at all times?

- Have we sufficiently trained them to read labels and SDSs, operate monitors/detectors, and respond correctly in case of emergency?

OSHA also requires a written hazard communication program setting out how the standard’s criteria are being met. Although it’s a time-consuming exercise, reassessing this plan (or creating one if you haven’t already done so) will encourage you to reexamine the HCS and give you the opportunity to correct any oversights or errors in your application of 29 CFR 1910.1200.

A top priority

Don’t forget to review the rest of OSHA’s “naughty” list and ask yourself if you’re in compliance with any standards listed there that affect your workplace. Would you be able to recognize violations if you saw them?

If not—or if you’re not sure—a meticulous review of these standards and subsequent examination of your jobsite is in order. To help you evaluate your worksite for the types of violations identified in the OSHA Top Ten, MSA Safety has designed a visual overview to get you started.

Sources:

[1] https://www.osha.gov/Top_Ten_Standards.html

[2] https://www.msdsonline.com/2019/09/10/oshas-top-10-most-cited-violations-of-2019/

[3] https://www.osha.gov/dsg/hazcom/index.html