For most people, autumn is the season for hayrides, changing leaves and apple picking. For HVAC professionals, autumn is the season for combustion analysis. As temperatures begin to drop, residential and commercial spaces begin turning up their thermostats and an unchecked furnace or boiler may lead to safety hazards, financial loss and wasted time.

How do heating systems work?

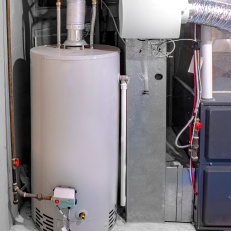

Inside a furnace or boiler, air is warmed by igniting a fueling source (heating oil, propane or natural gas) and then is pushed through a duct system by a blower, spreading the warmed air into various rooms and spaces. Cooled air returns to the furnace through a separate duct system, and the process repeats.

What is combustion analysis?

Combustion analysis is a careful test of the heat exchanger (the fueling sources mentioned above) in a furnace or boiler. The process of heating air involves the inevitable emission of harmful gasses, and combustion analysis is a way to check if the fuel-to-air ratio in the heat exchanger is safe and appropriate.

Why is combustion analysis important?

- Safety: Natural gas leaks can lead to serious safety risks if they’re overlooked. Carbon monoxide (CO) and carbon dioxide (CO2) can be fatal, and neither are good for the health of our planet in excessive amounts. Thankfully, with a well performed combustion analysis test leaks and unbalanced ratios can be fixed, creating sufficient oxygen (O2) and minimal or zero CO and CO2 emission rates. This regulation allows for safer indoor and outdoor environments.

- Efficiency: It’s no secret that well maintained machines run better and last longer. A properly tuned heating system requires less energy resulting in lower fuel expenses; and catching problems early can prevent unplanned repairs in the future saving you money and time. This diligence can also save natural fuels, a limited resource we have here on Earth.

- Troubleshooting: A well heated space doesn’t always mean the heating system is working at its best or safest capacity. Keeping with a regular combustion analysis schedule will ensure that any unexpected problems are caught and repaired early. Nothing beats the comfort of knowing your space is safe, night and day.

How often should I have a combustion analysis test completed?

HVAC professionals recommend having your heating system checked at least once a year, ideally before the start of winter. Annual tests are good for every space, however, regardless of the climate you live in.

What tools do I need to complete a combustion analysis test?

Trouble in a heating system can’t be found visually by looking at the flame, HVAC professionals must use combustion analyzers to study and measure the fueling sources. Each analyzer is different, and MSA offers a wide variety of handheld technologies that can ensure accurate readings and extensive reports.

PCA 400 Combustion & Emissions Analyzer

- Commercial & Industrial Applications

- Up to 4 gas sensors for O2, CO, NO, NO2 and SO2

- Wireless Bluetooth® connection to mobile app for real-time combustion measurements and remote operation

- Long life O2 sensor with 5 year warranty reduces maintenance costs and downtime

Insight Plus Combustion Analyzer

- Residential & Commercial Furnaces

- Provides readings for O2, CO, CO2, combustion efficiency, temperature and draft

- Tune-Rite HVAC assistant

- Long life O2 sensor with 3 year warranty

- Residential furnaces

- Provides readings for O2, CO, CO2, combustion efficiency and temperature

- Combustion App allows users to quickly create custom reports with comments and send via email (available for Android & iOS)

- Intuitive and fast menu navigation

Whether you’re testing a residential, commercial, or industrial area a regular combustion analysis practice is important for every space, and being diligent can only lead to increased safety.

Want to learn more about our complete line of combustion analyzers? Click here