Methane (CH₄) is a simple hydrocarbon and the primary component of natural gas. This colorless, odorless gas possesses several key properties that make it both a valuable resource and a potential hazard. Methane can be transported not only in gas form but also in liquid form at extremely low temperatures, which is the basis of the Liquefied Natural Gas (LNG) industry. The transportation and storage of LNG comes with its own set of specific and unique hazards. Strict safety measures and protocols can help to manage the risks associated with methane’s high energy content and the extreme conditions required to keep it in liquid form.

As we explore the explosive risk associated with methane gas leaks, we will consider not only its molecular composition and physical characteristics but also the safety concerns tied to the LNG sector. In this blog post, we will delve into the unique properties of methane, its flammability, and examine effective solutions to help prevent and address the perilous situations it can create, whether as a gas or in its liquefied state.

The Explosive Hazards of Methane Gas Leaks:

1. Flammability and Explosive Potential:

Methane, being a highly combustible gas, can form explosive mixtures with air in concentrations ranging from 5% to 15%. This property, combined with its odorless nature, underscores the need for vigilance in detecting leaks before they escalate into dangerous situations. When leaked into confined spaces, such as buildings or pipelines, methane can create an explosive atmosphere. Even a small spark or ignition source can trigger a violent explosion, leading to severe consequences for both individuals and infrastructure.

2. Infrastructure Vulnerability:

The physical state of methane as a colorless and odorless gas at room temperature and atmospheric pressure makes it challenging to detect without specialized equipment. Methane leaks in pipelines, storage facilities, or other infrastructure can result from corrosion, equipment malfunctions, or inadequate maintenance. These leaks not only release methane into the atmosphere but also expose these facilities to the risk of explosions.

3. Public Safety Concerns:

With a boiling point of -161.5°C (-258.7°F) and a melting point of -182.5°C (-296.5°F), methane transitions between states at extremely low temperatures. This property is what allows methane to be liquefied and transported as Liquefied Natural Gas (LNG), a critical component of the global energy industry. Effective detection methods and preventive measures can mitigate the unique hazards associated with both gaseous and liquefied methane, particularly in confined spaces and during LNG transport and store.

Solutions to Prevent Explosive Methane Gas Leaks:

1. Rigorous Inspection and Maintenance:

Regular inspections are crucial to identifying potential vulnerabilities in infrastructure, such as corroded pipes or faulty equipment. Understanding methane’s low boiling and melting points reinforces the need for thorough inspections, ensuring the integrity of the infrastructure even under extreme conditions.

2. Enhanced Leak Detection Technologies:

Utilizing cutting-edge technologies, including advanced gas sensors, can improve the detection of methane leaks before they escalate. Early identification allows for rapid response and intervention, minimizing the risk of ignition sources coming into contact with the leaked gas.

3. Emergency Shutdown Systems:

Implementing robust emergency shutdown systems in infrastructure can swiftly isolate and contain methane leaks in the event of detection. These systems are designed to prevent the escalation of leaks into explosive situations, safeguarding both the facility and surrounding areas.

4. Public Awareness and Preparedness:

The addition of odorants like mercaptan to natural gas, though not directly related to methane’s physical properties, plays a crucial role in public safety. Public awareness campaigns, coupled with clear guidance on emergency response procedures, further enhance community preparedness against the explosive hazards of methane leaks.

Gas Monitoring Methods for Methane Leaks

Detecting methane gas leaks is crucial for preventing environmental hazards and potential explosive situations. Several methods and technologies are employed for methane leak detection. Here are some common methods:

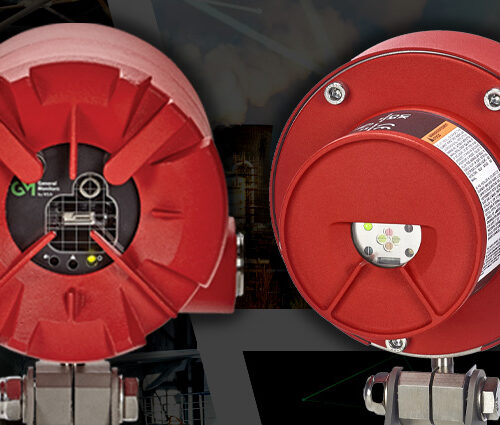

- Point Detectors: These are handheld or fixed devices that can detect methane levels in specific locations. They provide real-time readings and are often used in confined spaces or areas with known risks. Infrared and catalytic bead sensors are common detection methods.

Recommended MSA gas detectors: ULTIMA X5000, General Monitors S5000, ALTAIR io4

- Open Path Detectors: These sensors use infrared technology to detect methane along an open path between a transmitter and a receiver. Changes in the infrared light absorption indicate the presence of methane.

Recommended MSA gas detectors: Senscient ELDS, IR5500

- Acoustic Sensors: Acoustic (ultrasonic) sensors can detect the sound of gas escaping from leaks. This method is especially useful for identifying leaks in pressurized systems and can complement other detection methods.

Recommended MSA gas detectors: Observer-i Ultrasonic Gas Leak Detector

- Fire and Gas Detection Controllers: Used to power the connected methane fire and gas detectors and display measured gas concentrations. They can also monitor the limit values, actuate alarm devices, and initiate risk reduction measures.

Recommended MSA products: Fire and Gas Detection Controllers

Combining multiple detection methods can provide a more comprehensive and reliable approach to identifying and addressing methane gas leaks promptly. The choice of method often depends on factors such as the size of the area to be monitored, accessibility, and the severity of potential risks.

Conclusion:

Understanding the unique properties of methane, from its chemical composition to physical characteristics, is fundamental to addressing the explosive dangers associated with gas leaks. By combining rigorous inspection, advanced detection technologies, emergency shutdown systems, and community education, risks can be mitigated, helping to ensure a safer and more secure future for all.

* Based on NFPA flammability limits (International / IEC limits are often different e.g. ISO 80079‑20‑1 states 4.4% Vol. – 17.0% Vol. range for Methane).