After a five-year long process, the International Electrotechnical Commission (IEC) recently revised its 60335-2-89 standard to increase the flammable refrigerant charge size limits in self-contained commercial refrigeration appliances, such as display cases, reach-in cabinets, and serve-over cabinets. In fact, IEC 60335-2-89:2019 was published on June 20, 2019.

While the standard is voluntary (unless adopted into a national regulation and/or code), it provides critical equipment safety guidance and signals a stronger future for alternative refrigerants.

Thus, in this article, we will provide a rundown on how International Safety Standard IEC 60335-2-89 has been updated to allow larger quantities of flammable refrigerants in commercial refrigerating appliances and what this means for designers, installers, and operators. Let’s get started.

IEC Revises Standard 60335-2-89

The international effort to increase the flammable refrigerant charge size limit under under IEC standard 60335-2-89 was a five-year-long process. That is, in 2014, the IEC subcommittee (SC) 61C constructed a Working Group (WG4) to “define the maximum flammable refrigerant amount for appliances according to IEC 60335-2-89 and measures to maintain the equivalent safety level as for the present limit.”

The journey to amending this standard quickly became one of the most prominent standards activities for alternative refrigerants.

Now, the process to amend an IEC standard includes a total of six stages: the proposal stage, the preparatory stage, the committee stage, the enquiry stage, the approval stage, and the publication stage. Additionally, such amending can take from six months or up to five years, depending on the size of the project and the amount of differing technical opinions.

The amendment process for this standard took five years.

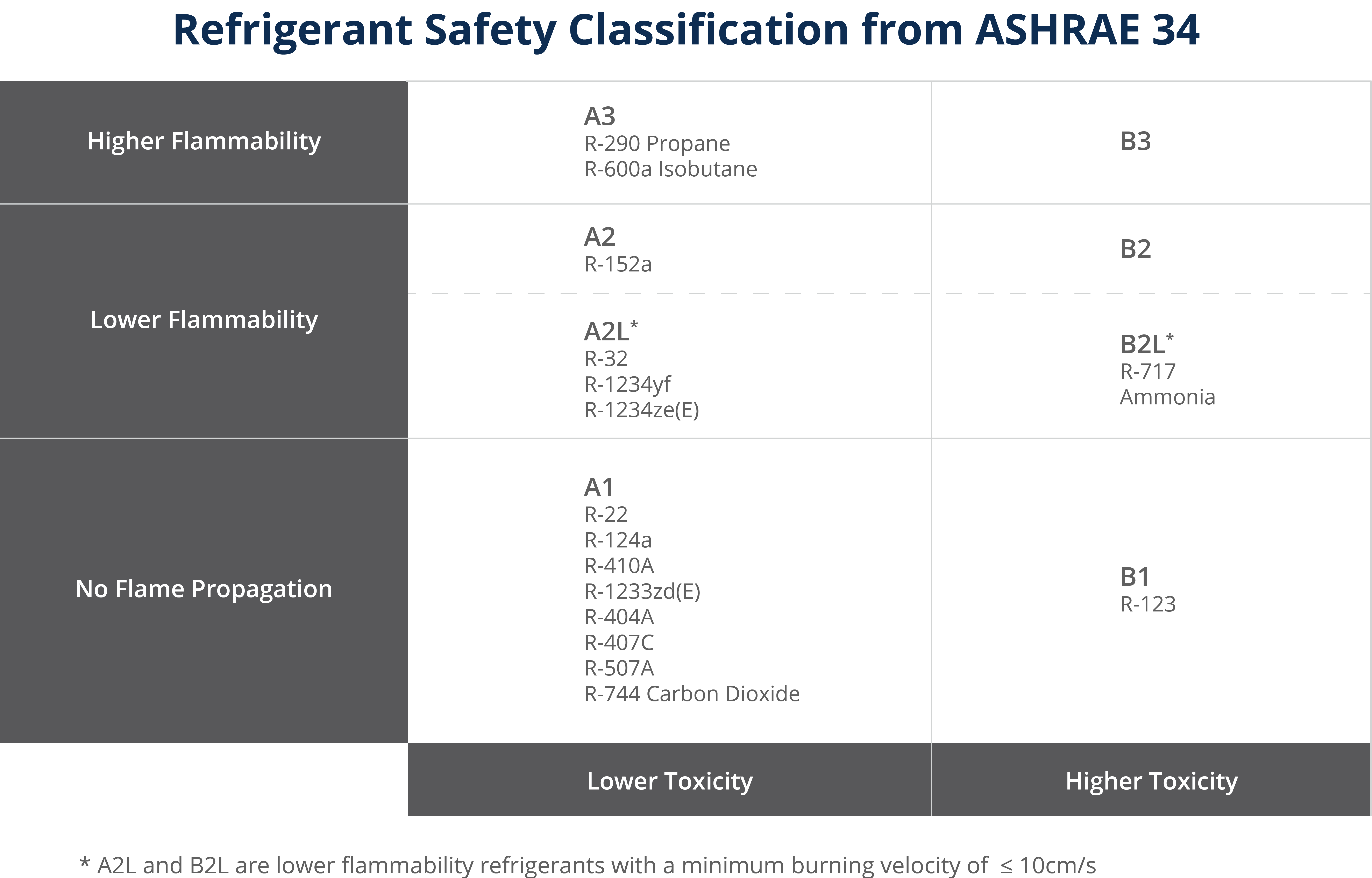

Indeed, on June 20, 2019, a consensus was reached and IEC standard 60335-2-89:2019 was published. The updated standard increases the charge limit for A3 (higher flammability) refrigerants along with A2 and A2L (lower flammability) refrigerants. (The refrigerant safety classification chart seen below provides an overview of the safety classifications of refrigerants based on ASHRAE Standard 34. As you can see, certain alternative refrigerants pose flammability and/or greater toxicity concerns.)

Keeping these classifications in mind, let’s explore in more detail the increased charge size limits for A3, A2, and A2L refrigerants in self-contained commercial refrigeration appliances:

Charge Size Limits Increase

The revised standard increases the limits on the flammable refrigerant charge size amount for commercial refrigerating appliances with an incorporated or remote refrigerant unit or compressor.

A3 Refrigerants

IEC Standard 60335-2-89:2019 increases the charge size limit for A3 refrigerants from 150 grams to 500 grams in self-contained commercial refrigeration appliances. A3 refrigerants have higher flammability and lower toxicity and include R-290 (Propane) and R-600a (Isobutane).

- Increases maximum allowable refrigerant charge size limit for A3 refrigerants

- A3 refrigerants include R-290 (Propane) and R-600a (Isobutane)

A2L Refrigerants

The revised standard also increases the charge size limit for A2 and A2L refrigerants from 150 grams to 1,200 grams in self-contained commercial refrigeration appliances. A2 and A2L refrigerants have lower flammability and lower toxicity. An example of an A2 refrigerant is R-152a and a A2L is R-1234ze.

- Increases maximum allowable refrigerant charge size limit for A2 & A2L refrigerants

- A common A2 refrigerant is 152a; common A2Ls are R-32 and R-1234ze.

Now, the fact that this revised standard took five-years to reach publication speaks to just how major of an undertaking it was; technical opinions differed largely and reaching a consensus was no easy feat.

Take the dramatic turn of events in the approval stage as a case in point:

In Last-Minute Turn of Events, IEC Votes to Approve New Standard

In April, the IEC held a Final Draft International Standard (FDIS) vote, in which 35 nations voted for the change, against, or abstained. If opposing votes exceeded the maximum limit of 25%, then the FDIS would not go through, and that’s what initially happened: There were “nine opposing votes from the 35 nations voting.”

However, there was a last-minute turn of events. You see, National Bodies must adhere to proper voting procedures. That is, “If a national body votes positively, it cannot submit any comments. If a National Body finds the Final Draft International Standard unacceptable, it must vote negatively and state the technical reasons.”

The latter half of this sentence—must vote negatively and state the technical reasons—is where things got messy. In fact, Malaysia, who voted against the revision, did not provide any technical reason as required. As a result, this vote was rejected, and thereafter the amended Standard passed the approval stage and proceeded to publication. The Cooling Post describes this series of events as a “remarkable recount.”

In sum, after a dramatic and last-minute turn of events, the revisions to IEC Standard 60335-2-89 passed, allowing larger charge sizes of certain alternative refrigerants in commercial refrigeration appliances.

Bacharach Helps You Achieve Refrigerant Safety Compliance

Codes and standards for alternative refrigerants continue to evolve, and we are here to keep you updated and achieve refrigerant safety compliance.

As the refrigeration industry turns more towards low-GWP alternative refrigerants, Bacharach has an extensive library of refrigerant gases, including for R-290 (Propane) and R-600a (Isobutane), which can be detected and monitored to support such industry movement.