When a customer decides to move ahead with the installation of a new fixed flame and/or gas detection system, we can’t help but get excited, and not for the reason you might think! As a company centered on safety, we have a passion for properly installed and operating safety systems and see this decision as a commitment to saving lives, and at minimum ensuring their people and contractors may work in safety and that they, their families, and their communities may live in health. On top of that, we always work to ensure our customers attain the maximum benefit and overall top system performance and protection possible. With that being said, here are some best practices for end users to consider getting their new detection system installed, commissioned, and operating to deliver 24/7 year-round protection.

Installation Best Practices

Fixed flame and gas system installers should be qualified, licensed, and understand what it is they are installing. This means the installers need comprehensive, detailed documentation on exactly what is being installed, and why! If there is a gap here, we recommend that a small amount of installer training will go a long way! Be prepared to make this training available with emphasis on your specific system installation requirements. In addition, here is a short list of typical physical installation recommendations:

- The system power supply should be properly sized and of proper type/rating. If a back-up power source is required, the status of this back-up system should be monitored, and it must be properly sized. The power distribution design should also include sub-breakers to enable powering up/down the system in logical sections rather than just all at once.

- The system should be monitored for ground faults. Even if it is not required by code, it is a best practice for installers to proceed on the premise that ground fault monitoring is required.

- All detector power and signal cabling requirements should be clarified including cable shields and terminations as required. Don’t forget that conduit seals, breathers, & drains are recommended and flexible conduit within 1 meter of a flame detector to enable proper flame detector aiming/alignment is generally required.

- Detector mounting location structure must be solid and robust. Mounting structure vibration and movement is wholly undesirable and can lead to nuisance alarm problems. Also, all detection instruments should have a field tag attached with an instrument tag number easily visible.

- A flame and gas detector setup table spreadsheet is recommended identifying instrument tag numbers for all detectors, installation location/elevation using GPS coordinates, programmable settings including sensitivity, time delay setting, latching or non-latching relay configuration, normally energized or normally de-energized relay coils, calibration information (gas detectors), and other configuration settings.

Commissioning Best Practices

After installation is complete and the system and all field devices are powered-up and operating in a 100% fault-free mode, system commissioning can commence. It is important to note that system commissioning and integrated testing are two different concepts, and both must be completed successfully to properly evaluate the flame and gas detection system operation as well as its interaction with other systems.

Commissioning is a systematic process that provides documented confirmation that all system functions according to the intended design criteria set forth in project documents and satisfy the owner’s operational needs, including compliance with applicable laws, regulations, codes, and standards. A commissioning checklist is generally developed that spells out specific system functions, critical input and output signals, devices, and operational logic that must be tested and validated before the system can be considered fully commissioned. The commissioning checklist typically includes line item checks for:

- proper functional testing of power redundancy/battery back-up

- system ground fault monitoring

- critical output functions and related input actuation

- field testing methodology for all flame detectors and manual fire alarm signaling devices including alarm voting criteria (cross-zone or multi-sensor confirmation)

After completion, the Commissioning Engineer typically prepares and submits a commissioning report including as-built drawings, cause/effect logic, and updated system database of all information developed, changed or modified during the full commissioning process.

Operations, Maintenance, and Training

Operations and Maintenance personnel are the ones generally assigned to keep the fire and gas system operating and ready. This means that these same folks have responsibility for maintaining a fire and gas detection system maintenance logbook! This logbook generally includes the means to document all system activities and events, logged by instrument tag number. Typical logbook entries include fire and gas alarms, faults, visual inspections, gas detector bump tests and/or calibrations, functional tests using a test lamp, and cleaning activities logged by tag number, date & time, and person. In addition, a routine visual inspection procedure should be established where the frequency of visual inspection points is defined.

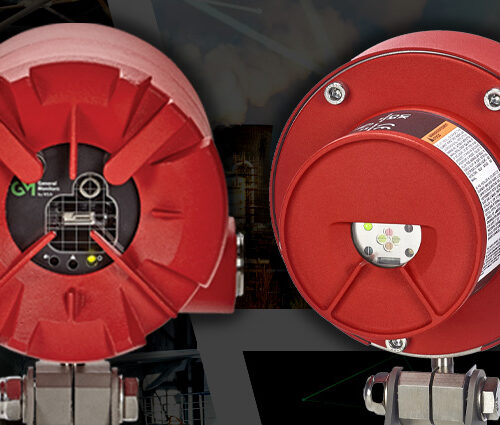

This means that detector faceplate status LED’s should be routinely visually inspected as a check for normal or trouble status, along with confirmation that no foreign material or obstructions are present that will block the operation of any detector, and that alignment angles appear normal. If there are any protection accessories installed, these should also be inspected to ensure they are working properly. Finally, a functional test using a test lamp should be routinely executed for flame detectors. Be sure to bypass any suppression discharge apparatus before performing a functional fire detector alarm test.

We know that new employees are constantly brought into our customer’s organizations and that in some cases, comprehensive training programs on the fixed flame and gas detection system may not exist in a documented format for these new hands. For this reason, following below we have detailed some of the most basic system operating procedures that Operations and Maintenance Technicians should be able to perform and understand:

- where to find the system logbook, instruction manuals, and electrical schematics

- what is the recordkeeping procedure for logging troubles, alarms, cleaning activities etc.

- how to identify where and when an alarm or fault occurred

- how to bypass the alarm function on a system for routine detector service

- how to perform a visual inspection

- how to troubleshoot a basic trouble/fault condition

- how to communicate with a detector using HART

- how to perform a response test

- how to Power up/Power down a system

- what is the annual system inspection and alarm response testing plan

- who to call for technical assistance?

Please note the above mentioned best practices are only a short list of typical or most common system requirements and not intended to cover all possible system types or configurations. We recommend always contacting your local fire department and/or Authority Having Jurisdiction (AHJ) for specific guidance on your local or national compliance requirements.

Want to learn more? Watch our Best Practices for Fire & Gas Detection Applications webinar to learn more about the considerations for installation, commissioning/testing, operation & maintenance and system training.