In most cases, the only way of knowing there’s a refrigerant leak in a supermarket is when the equipment fails. At this point, it’s too late to avoid the loss of food quality, damaged stock, and replacing the costly refrigerant.

It doesn’t have to be like that. The MSA Parasense Enterprise Leak Detection (ELD) Platform provides early, low level refrigerant leak detection and notification which means as soon as a leak is found, rapid repairs can be arranged, saving stock, refrigerant, and revenue.

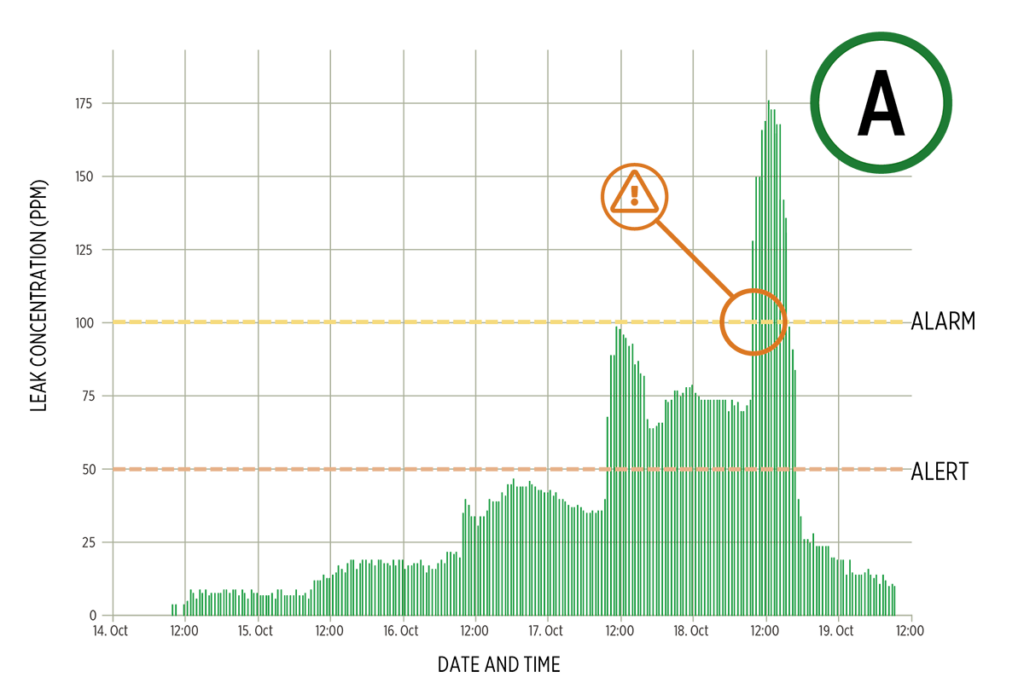

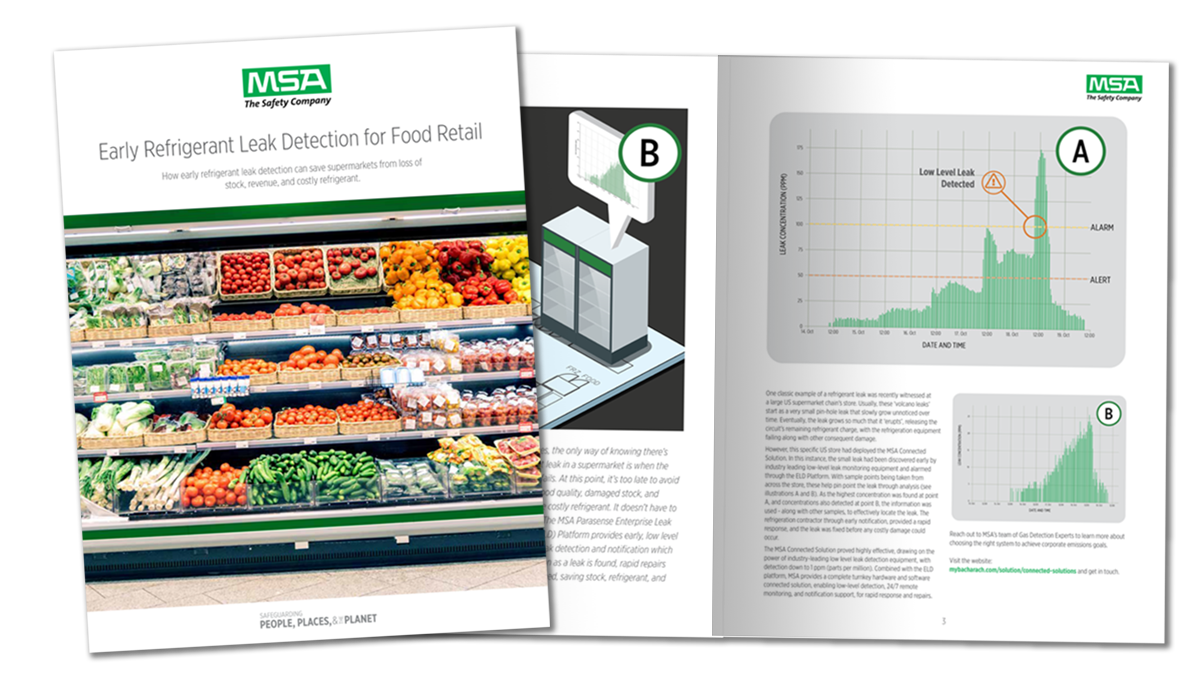

One classic example of a refrigerant leak was recently witnessed at a large US supermarket chain’s store. Usually, these Volcano Refrigerant Leak Patterns start as a very small pin-hole leak that slowly grow unnoticed over time. Eventually, the leak grows so much that it ‘erupts’, releasing the circuit’s remaining refrigerant charge, with the refrigeration equipment failing along with other consequent damage.

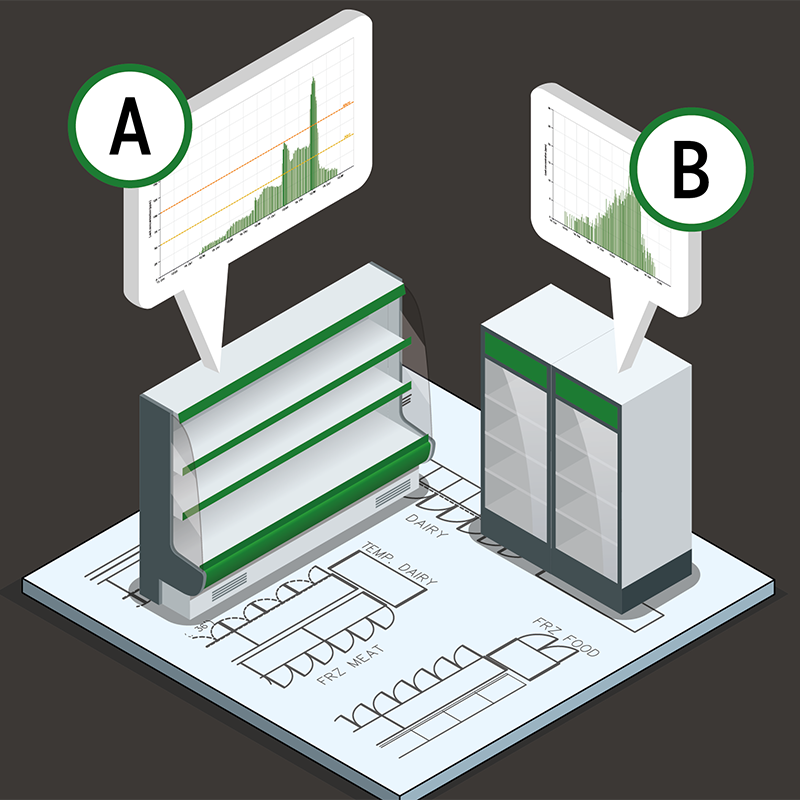

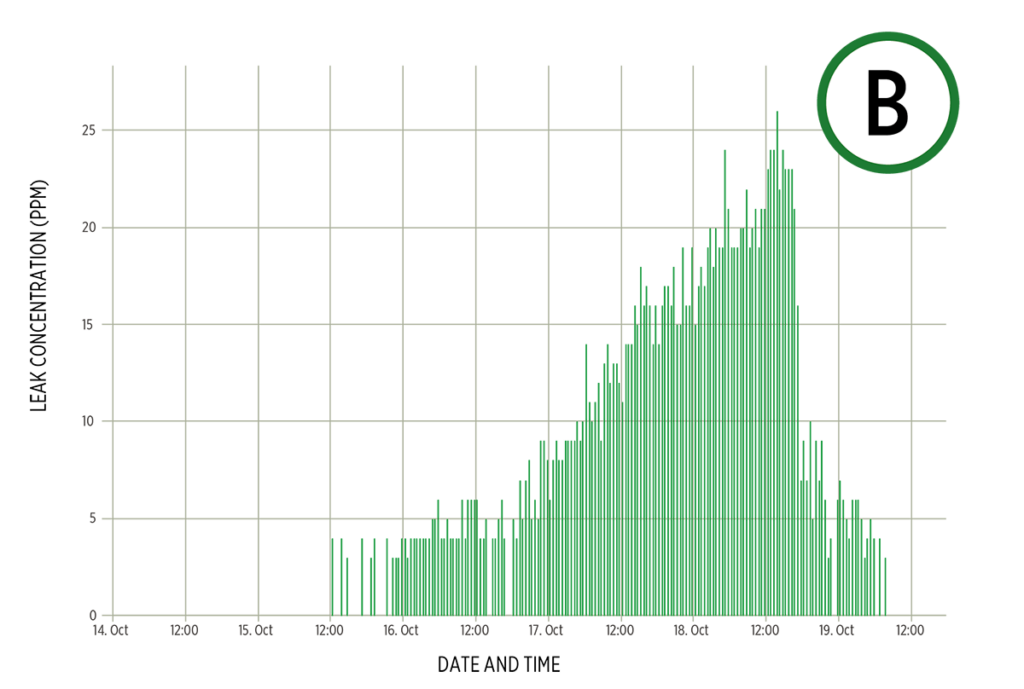

However, this specific US store had deployed the MSA Connected Solution. In this instance, the small leak had been discovered early by industry leading low-level leak monitoring equipment and alarmed through the ELD Platform. With sample points being taken from across the store, these help pin point the leak through analysis (see illustrations A and B). As the highest concentration was found at point A, and concentrations also detected at point B, the information was used – along with other samples, to effectively locate the leak. The refrigeration contractor through early notification, provided a rapid response, and the leak was fixed before any costly damage could occur.

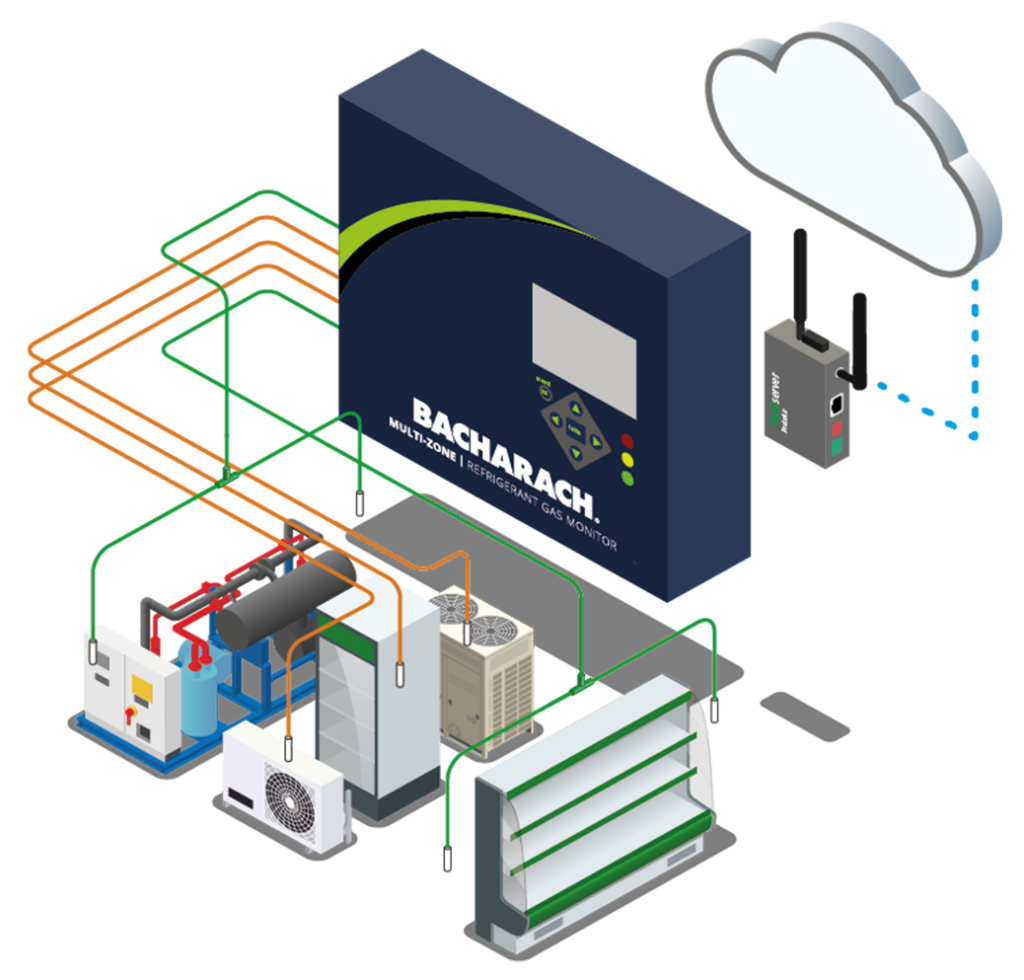

The MSA Connected Solution proved highly effective, drawing on the power of industry-leading low level leak detection equipment, with detection down to 1 ppm (parts per million). Combined with the ELD platform, MSA provides a complete turnkey hardware and software connected solution, enabling low-level detection, 24/7 remote monitoring, and notification support, for rapid response and repairs.

Background Refrigerant Monitoring

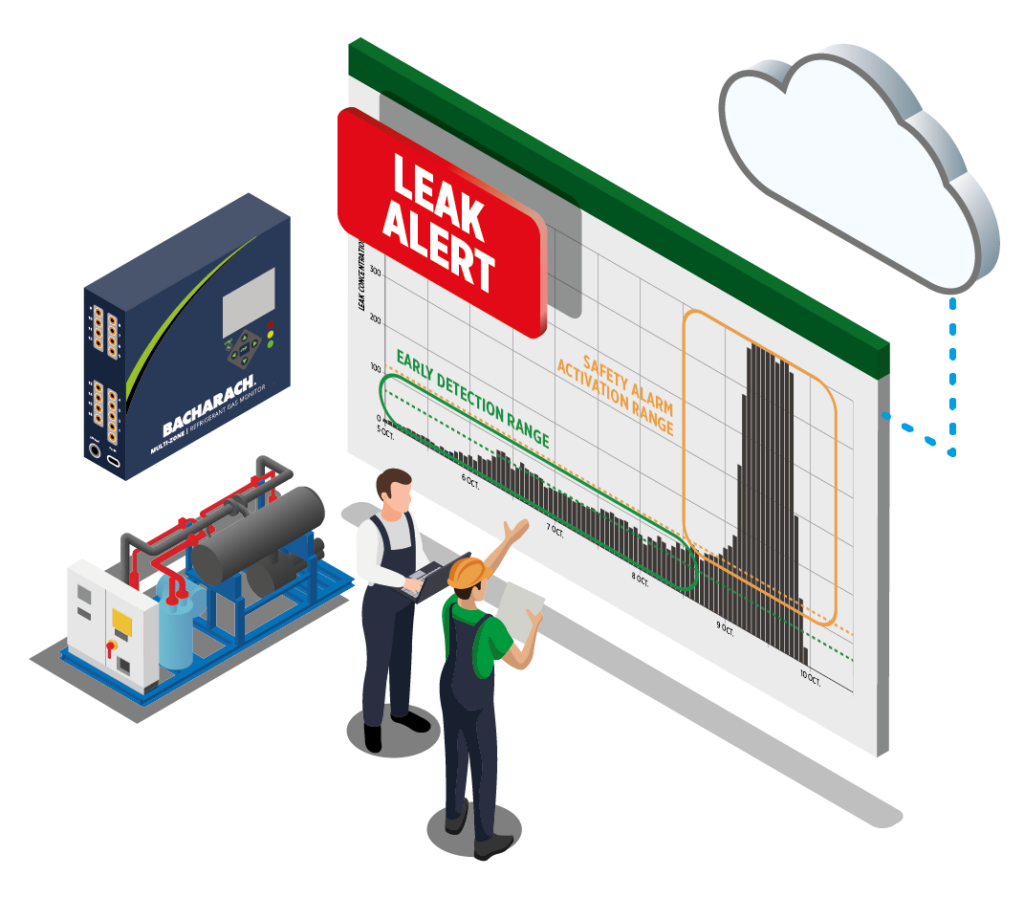

The Multi-Zone gas monitor provides industry leading detection down to 1 part per million (ppm). Additionally, one monitor can detect up to 16 zones and expand with up to 48 sample locations. This allows effective monitoring of the prominent refrigerant leak locations of racks, walk-in boxes and sales floor cases by one single MZ monitor. Connecting the Multi-Zone to the MSA FieldServer IoT Gateway provides a secure IoT connection to the Parasense Enterprise Leak Detection (ELD) and Refrigerant Tracking and Compliance software.

Enterprise Notification & Rapid Response

The complete Parasense enterprise connected solution provides live event monitoring of the entire store portfolio in real-time. This means that should a refrigerant leak be detected within the monitored store, and for all the other stores in the chain, the enterprise software notifies the relevant teams immediately.

On-Site Low Level Portable Leak Detection

The complete Parasense enterprise connected When a leak is found within the store, it’s important to accurately pin-point and fix the leak as quickly as possible, minimizing downtime and potential hazards. This is where the portable Bacharach® PGM-IR, with the same industry leading infrared sensing technology as the Multi-Zone, can find leaks fast down to 1PPM.

Download your copy of this success story and find out how MSA Safety’s Connected Solutions experts can help you reduce your refrigerant emissions.

Download the PDF