Being responsible for the installation and upkeep of a reliable gas monitoring system in any facility is an important task that should not be taken lightly.

Industrial, commercial, and public sector buildings often utilize some amount of toxic gases in the general running of their operations. For example, HVAC-R systems used to keep buildings at ambient temperatures, chill cold storage rooms, and circulate fresh air can leak refrigerant gases. Additionally, various gases can be found in heavy-duty industrial cleaning equipment and as the byproduct of manufacturing processes in production facilities.

Installing Gas Detectors for Safety Compliance

Despite best efforts, refrigerant leaks can still occur. Prompt detection can allow users to deal effectively with leaks.

Gas detectors, like the MSA Bacharach® MGS-400 series, actively monitor a building’s atmosphere for a target gas and emit a warning signal when a set threshold is surpassed. These monitors can form part of an integrated network built into your building control systems and may help achieve refrigerant safety compliance. A more advanced building network of monitors and control systems helps provide peace of mind for occupants’ and personnel’s health and safety.

Considerations for Successful Gas Detection

The first step in preparing for a potential gas leak is to have a network of properly installed and well-maintained gas detection units in place throughout the building. Following these simple guidelines can help better position a facility’s gas monitoring system for quick and efficient detection of a target gas should a leak event occur.

Choosing the Correct Number of Sensors

When choosing how many sensors to install, safety managers may wish to to err on the side of caution and get as many units as are required to provide maximum coverage. Because gas monitors patrol a fixed point, not a general area, users often choose to monitor any space that may be directly exposed to gas.

For personnel safety, gas detector sensors are generally installed no more than 16.5 feet (5 m) from a potential leak source.

Selecting Where to Position Gas Detectors

For a gas detector to effectively serve its purpose, it should be installed where it can be seen, heard, and be able to detect a potential leak. Installers should mount monitors according to the product dimensions, maximum wiring lengths, and guidelines outlined in a product user manual. Other important considerations include:

- Physical Characteristics (Specific Gravity) of the Target Gas

- Environmental Conditions

- Specifics of the Application

- Accessibility to Personnel

Environmental Conditions

Installers should account for a wide range of environmental conditions when selecting a location to mount a gas detector.

Avoid Adverse Conditions

Gas detectors should not be installed in locations where they will be subjected to elements that are outside of the device’s specifications (for example, extreme temperatures, high humidity, high concentration of airborne particles). It is important that the instrument’s Ingress Protection (IP) rating is sufficient to protect its sensitive electronics.

It is also important that sensors should not be installed where they are likely to be damaged during daily use of the space. Such environments may impact the instrument’s ability to detect the target gas effectively.

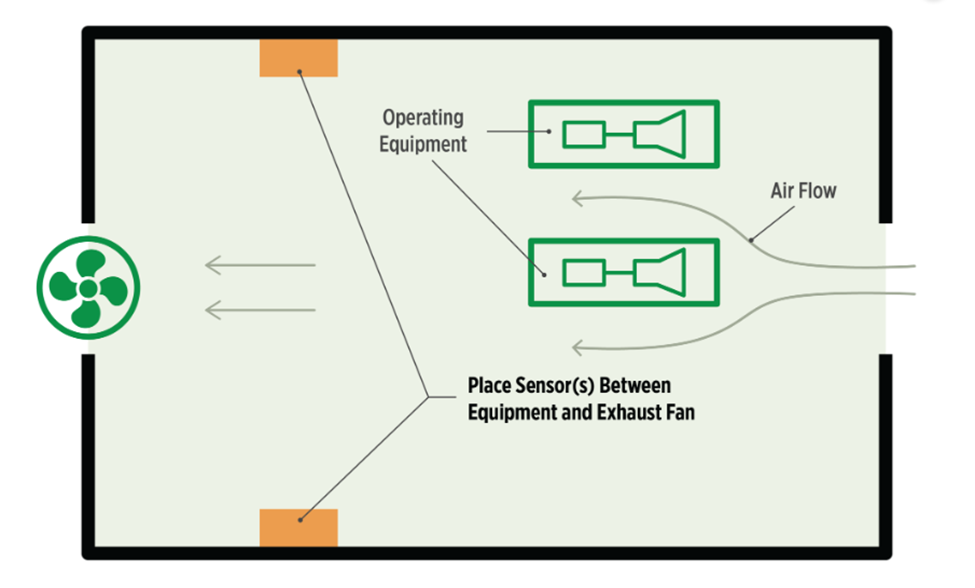

Account for Currents / Airflow

Installers should consider the airflow in the monitored space. Room ventilation can alter the airflow pattern and affect how efficiently the target gas is monitored. In other words, installers should consider how escaping gas may behave due to air currents. A smoke test may be conducted to determine optimal placement. If appropriate, an installer may choose to mount gas detectors in ventilation ducts.

High airflow can dilute the target gas. Because of this, placing sensors closer to a potential leak source may improve leak detection in spaces with high airflow.

Installers should avoid placing a refrigerant gas detector in an area where airflow may become obstructed. This commonly occurs in walk-in freezers where personnel may (inadvertently) push boxes against the instrument. Obstructed airflow to the sensor may result in ineffective leak detection.

Specifics of the Application

Installers may choose between perimeter detection and point detection when positioning gas sensors in a monitored space.

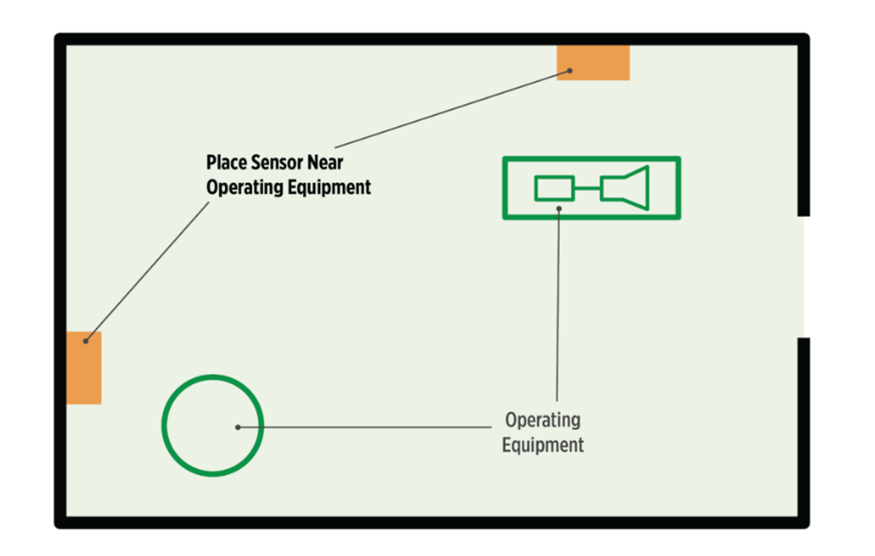

Point Detection

Point detection involves mounting the gas detectors at specific points where refrigerant leaks may occur. For example, installers may choose to position gas detectors close to compressors, expansion valves, mechanical joints, or cable duct trenches. If a leak occurs, there’s a higher chance of encountering the highest concentration of the target gas in those areas.

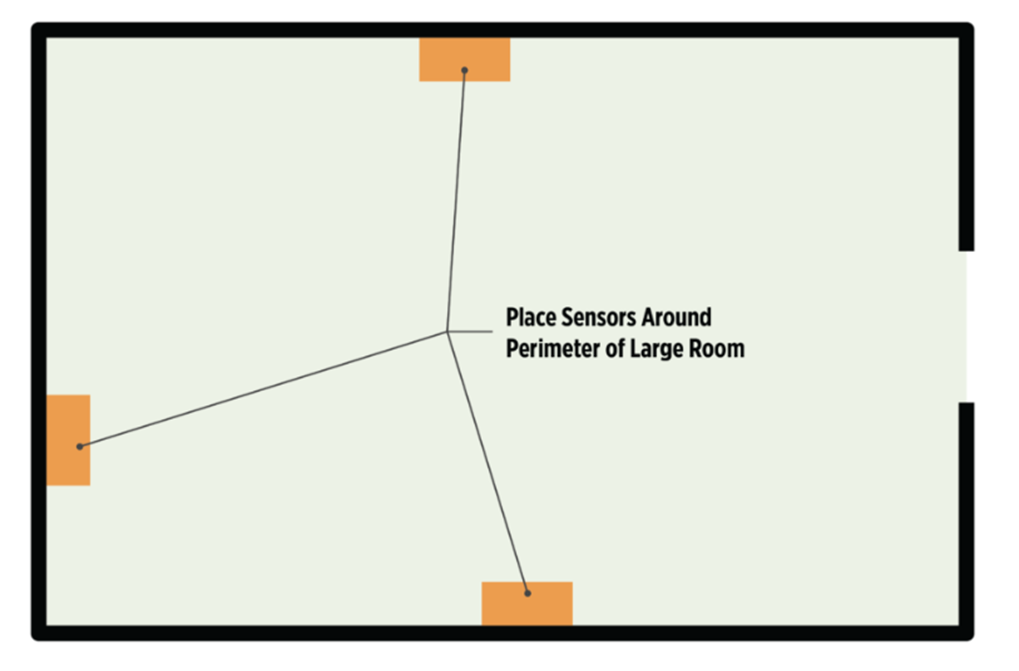

Perimeter Detection

Perimeter detection involves placing gas detection units all around the perimeter of the monitored area. This may be a preferred option when it is difficult to locate sensors near a potential leak source. A drawback of perimeter detection is that the target gas may become diluted before it reaches the gas detector.

Accessibility to Personnel

Gas detectors require regular maintenance to ensure functionality. Where possible, they should be installed in an area that is easily accessible for functional testing and servicing.

Instruments featuring a remote sensor(s) allow installers to monitor for refrigerant leaks in inaccessible locations without forfeiting convenient access to electrical / communications wiring.

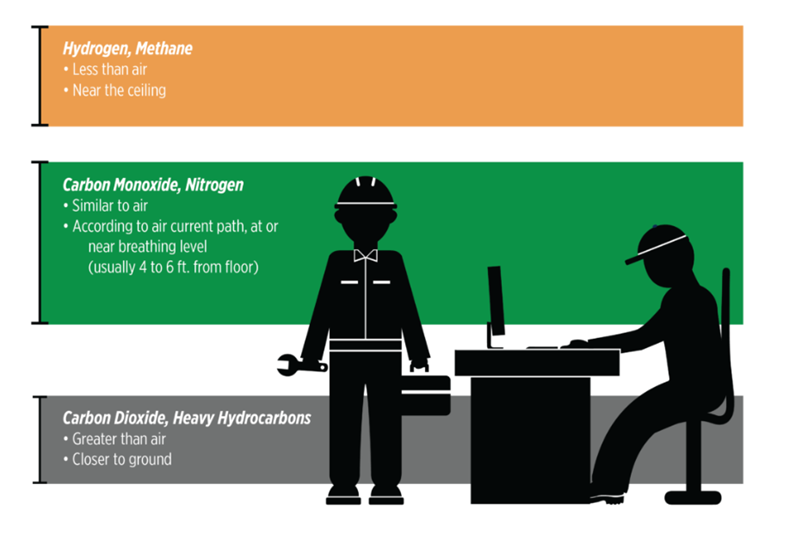

Physical Characteristics of the Target Gas

It’s important to consider the heaviness or lightness (specific gravity) of the target gas. Sensors used to detect gases heavier than air – such as butane, propane, LPG, or ozone – should be placed close to ground level. Gas detectors meant to detect the presence of gases that are lighter than air – such as hydrogen, methane, and ammonia – should have monitors located closer to the ceiling. Equal density gases should have monitors mounted at head height (usually 4 – 6 feet from the ground).

Effective Gas Detection is Important to Safety

The health and safety of personnel, the public, and the surrounding environment are largely dependent on the safe usage, storage, and disposal of hazardous substances and materials. To promote safety, commercial and industrial users are choosing to actively monitor gases that are the by-product of building operations or processes (such as HVAC systems and industrial manufacturing, storage, and cleaning processes).