If you’re responsible for keeping track of refrigerant usage and compliance such as EPA 608, CARB, GreenChill or F-Gas in your organization then you know how important it is to have a system that’s both reliable and easy to use. Find out what the options are for refrigerant usage tracking and compliance, while we take a look at possible systems and solutions and how they weigh up with the growing requirements for regulatory compliance

Why Track Refrigerant Usage?

The main purpose of tracking your refrigerant usage is regulatory compliance. All refrigerant regulatory compliance requires some form of refrigerant usage tracking. For instance, the US Environmental Protection Agency Section 608 of the Clean Air Act (EPA 608) requires reporting on a variety of conditions including specific ‘Chronically leaking report’ which states that all notifications to be submitted electronically (unless there’s confidential information contained). The California Air Resources Board (CARB) Refrigerant Management Program (RMP) requires facilities with refrigeration systems containing more than 50 pounds of high GWP refrigerant to conduct and report: periodic leak inspections, promptly repair leaks and keep service records on site with an added requirement to minimize refrigerant emissions.

What Should a Refrigerant Usage Tracking System Do?

You will need a system that can capture and report on a wide range of data such as what refrigerant you are using and how much, where your refrigerant is used across your site(s) and in what equipment. The system should also record when and where routine checks for refrigerant leaks took place. If a refrigerant leak was found, the system needs to record how the leak was resolved and when. Follow-up checks and actions are also required for compliance along with leak rate calculations across your organization, site or for specific pieces of equipment. Last but not least, you never know when you’ll be asked to report on your refrigerant. That’s why your documentation and system should be able to create reports at a moment’s notice.

What Are the Options?

A couple of sayings come to mind- ‘use the right tool for the right job’ and ‘you don’t need a sledgehammer to crack a nut’. The size and scale of your operation or organization will help you decide on what the right solution is for you. Keep in mind how much time you have to track refrigerant and measure this against how practical the tool is for your needs along with efficiency. The options mentioned here all have their uses:

- Paper-trail Systems

- Spreadsheets

- Building Management Software

- Refrigerant Usage Software

Let’s have a look at each of these in more detail:

Paper-Trail Systems

Paper-trail systems such as on-site paper reports, log books and financial records are often dismissed although can play an important role in recording refrigerant usage tracking. On-site records are required and log books can be used effectively for recording a wealth of information.

Financial records and invoices can also be effectively used to show the cost of refrigerant and date of purchase. However, this does not necessarily allocate the refrigerant itself to the piece of equipment or site.

In practical terms, paper-trail systems are not scalable for larger organizations or enterprises and integrating with work scheduling activities can be cumbersome. However, for a single site with a small amount of equipment, paper-trail systems can be quite effective up to a certain point.

Spreadsheets

Spreadsheets are a great step-up from paper-trail systems and there are plenty of online spreadsheet solutions out there that allow multi-user access for teams. Similarly, having the data available electronically means it’s scalable to a larger extent and can provide integration with calendars and work scheduling. However, to ensure regulatory compliance for workflows in relation to specific legislation, it’s important that the spreadsheet programmer is knowledgeable enough to ensure all the compliance steps are logged and maintained correctly.

Another consideration to make when deciding to use spreadsheets is who will be responsible for maintaining formulas and calculations when compliance regulations and reporting requirements change. In general, spreadsheets are great for small teams with a small number of sites and pieces of equipment per site but it is important to maintain your workflow to guarantee regulatory compliance.

Building Management Software

When looking for refrigerant usage tracking software for larger numbers of sites on an enterprise scale, with multiple pieces of refrigeration equipment, paper-trails and spreadsheets would be hard pushed to provide the efficiency you need.

Ideally suited for Facilities Managers to manage their building portfolios and enterprises, building management software as a whole can be extremely effective. When it comes to regulatory compliance, costs can begin to mount up if a modular approach to the software is taken by the development company. Along similar lines, development companies looking towards a full business management software suite may not be fully knowledgeable of changing regulatory compliance and may often create workflows that deviate from actual working methodologies within the refrigeration and HVAC industry.

Building management software can be a great route to take although it’s often noted that these systems are clunky to use- asking for too much data or too little data that can be effectively used for refrigerant regulatory compliance. Understandably, building management software works well at managing building controls but is generally not as effective as a purpose built refrigerant usage tracking system for compliance.

Specialized Refrigerant Usage Software

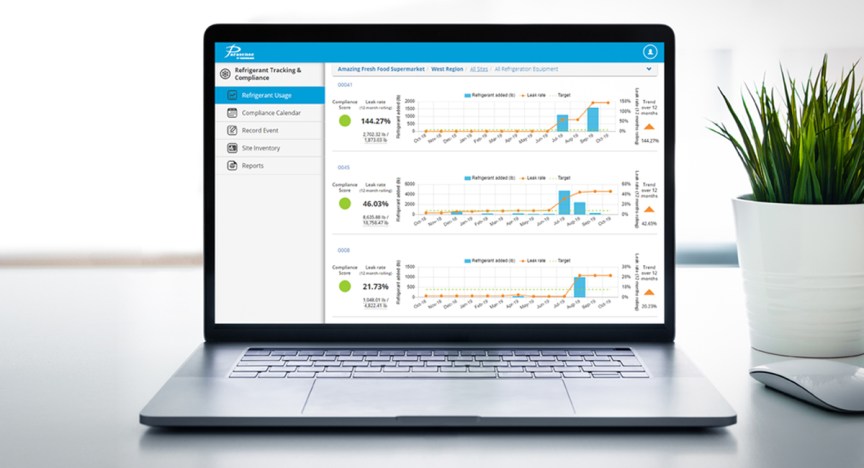

Specialized refrigerant usage software that helps you keep track of your refrigerant across your entire enterprise- including assets and sites can be seen as the holy grail for compliance. While often being fully accessible online, this solution can be ideal for remote refrigeration contractors and technicians as well as facility management teams.

Specialized refrigerant usage software can be perfectly aligned to your operational needs. The software is often developed by teams from within the refrigeration and HVAC industry, who know their regulatory compliance requirements- meaning that the system provides clear peace of mind for facility managers and refrigeration contractors alike. With “Goldilocks” data input requirement (not too much, not too little but just the right amount of data logging) to ensure regulatory compliance. This is especially useful for refrigeration contractors who require on-site data entry at a moment’s notice and not get bogged down entering irrelevant information- allowing more time fixing leaks than carrying out admin.

However, one thing to consider is cost. Similar to that of building management software, costs can be relatively high for specialized refrigerant usage software. Also take care in how costs are calculated, sometimes additional users, sites or equipment is chargeable as your organization grows. One good thing to know is that the MSA Parasense Refrigerant Tracking and Compliance software is an exceptional value and comes complete with a wealth of support information and videos to get you started in no time.

Maintain Regulatory Compliance

Before you decide which refrigerant tracking and compliance system is right for you or even before you begin to consider alternatives, request a demonstration of the powerful RTC software.