Light, simple, abundant. That’s hydrogen (H2). Because hydrogen doesn’t create carbon dioxide (CO2) emissions when burned, it holds the promise of becoming essential for global energy transformation, pollution remediation, and decarbonizing the planet.

In fact, H2 production, distribution, and usage is skyrocketing, having been fueled, in part, by environmental legislation and worldwide demand for clean energy.

H2 is extremely attractive as a fuel source because of its ability to be both environmentally friendly and sustainable. However, before adoption of hydrogen becomes even more widespread there’s work to be done; namely, H2 must be produced, distributed, and used safely.

Despite hydrogen’s potential to become a widespread clean-energy source, there are very real safety issues to contend with. Therein lies the challenge and the paradox.

On one hand, hydrogen’s unique chemical properties make it an exciting fuel alternative. On the other hand, those same properties are what hold the potential for these dangers:

- Hydrogen has a propensity to leak.

- It is colorless, odorless, and tasteless, making it undetectable by human senses.

- Hydrogen has an invisible, high-temperature flame with low thermal radiation.

- It is fast detonating and more explosive than natural gas.

Leak Monitoring and Detection

According to the U.S. Department of Energy, all fuels—including hydrogen—pose some degree of danger. While hydrogen’s non-toxic nature and ability to dissipate quickly when released are just a few of the reasons hydrogen may be safer to handle than other fuels, there’s still a need for safe use.

Specifically, hydrogen has a wide range of flammable concentrations in air and lower ignition energy than gasoline or natural gas, which means it can ignite more easily. Consequently, adequate ventilation and leak detection are important elements in the design of safe hydrogen systems. Because hydrogen burns with a nearly invisible flame, special flame detectors are required.[1]

“Safe Use of Hydrogen” [Energy.gov.]

Consistent monitoring, therefore, is imperative for hydrogen producers, distributors, and users.

The question is, how?

Although the need for monitoring and detecting hydrogen leaks is a relatively new challenge, here’s the good news …

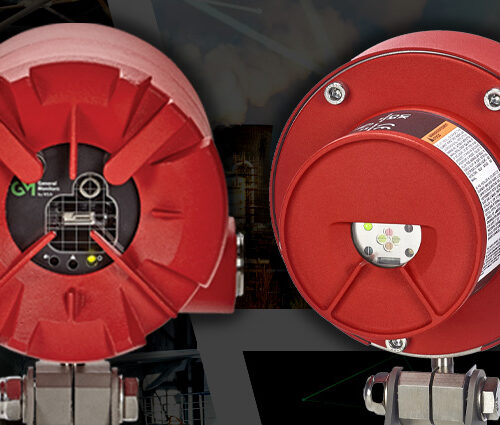

Here at MSA, we’ve been at the forefront of hydrogen gas and flame detection solutions. As one of the world’s largest and most experienced global suppliers of gas and flame detection equipment, MSA has pioneered the detection of combustible gases like hydrogen, methane, and propane.

In fact, our in-house Research and Development team develops, tests, and manufactures its own fully certified portfolio of products and safety solutions—including the very latest hydrogen gas and flame detection technologies.

Hydrogen Safety: Standards and Technologies

Protecting workers and facilities from dangerous hydrogen gas leaks always starts with understanding the standards and taking measures to comply with them.

For H2 gas, the international standards for explosion protection include IEC 60079 and IEC 80079, as well as specific standards (ISO 22734 and ISO 19880) for hydrogen facilities. You can delve into the specifics of these and other local standards. Suffice it to say, however, that there are many potential hydrogen-related hazards.

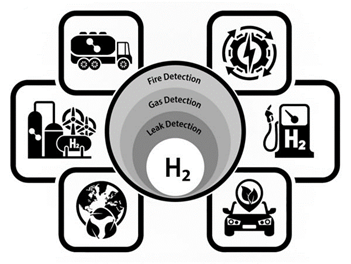

Which is why we recommend a layered approach to fire and gas protection.

By employing several distinct (yet complementary) technologies, facilities can run the detection gamut, including ultrasonic, conventional gas, and flame.

These technologies may include:

- Ultrasonic leak detection: Unaffected by wind or plume direction; ideal for monitoring pressured pipes and vessels

- Point gas detection: Well-suited for low and combustible hydrogen levels; options of catalytic or electrochemical, depending on the protection area

- Hydrogen flame detection: Best for monitoring infrared (IR) and ultraviolet (UV) radiation; provide a warning to deploy fire suppression and other safety measures

- Portable gas detection: Enables workers to access areas where sensors are not installed, such as a confined space

H2 Safety: Strategies for Planning Detection

Earlier we established that hydrogen gas presents exciting commercial and sustainability opportunities, as well as several new and distinctive challenges across the production and distribution chain.

Typically, design, installation, and planning of a layered gas and flame detection system for process industry facilities begins with choosing correct instrumentation for specific potential hazards. It also involves figuring out the particulars, including sensor detection range, mounting, and positioning, field of view, knowledge of lines of sight, and blind spots.

Because hydrogen gas detection and monitoring poses unique safety challenges, organizations entering (or already engaged in) the hydrogen supply chain should seek guidance from a safety partner like MSA. Through our fire and gas mapping solution, MSA offers hydrogen customers a technical assessment based upon recommendations outlined in the ISA TR84.00.07 Technical Report.

MSA’s solution delivers:

- Calculated metrics derived through proprietary mapping software

- Data-informed mapping report featuring correct placement, scope of gaps in coverage targets, and numerical estimates of detection coverage to increase the likelihood of early detection of hydrogen gas dispersal or fire

- Quantitative measure of gas detection needs to complement conventional methods based on coverage calculations

MSA’s proven track record is backed by sector-specific insight and expertise, so we can help you learn more about the safety risks and challenges of hydrogen.

Ready to dive deeper into hydrogen best practices, safety measures, and detection technologies? Download our Hydrogen Safety white paper or talk to an expert today.

References

- Energy.gov. “Safe Use of Hydrogen,” Retrieved 7 February 2023. (https://www.energy.gov/eere/fuelcells/safe-use-hydrogen)