By now, almost everyone in the HVAC-R industry should be well-aware: The R22 refrigerant phase out in the U.S. has almost reached completion. Yes, indeed, on January 1, 2020, there will be no more production or import of R-22; servicing needs will come only from recovered and reclaimed R-22, along with R-22 stockpiles.

Thus, one of the most widely used refrigerants will soon be obsolete… This is the long-anticipated R22 refrigerant phase out, and those without a plan could have their operations unexpectedly disrupted.

Essential Guide to the R22 Phase Out

That’s why we’ve created this essential guide for the R22 refrigerant phase out, including why this refrigerant is being phased out; what to possibly expect in the months ahead; and what you need to know about alternative refrigerant options for various applications. Let’s get started.

Why is R22 Being Phased Out?

Popular Refrigerant Choice Has A Caveat

First and foremost, HCFC-22, commonly referred to as R-22, is an efficient, non-flammable, and non-toxic refrigerant. However, the caveat with this popular refrigerant is the fact that it is an ozone-depleting substance (ODS).

It is classified as a hydrochlorofluorocarbon (HCFC) refrigerant and has an ozone depletion potential (ODP) of 0.055 and a global warming potential (GWP) of 1810 tCO2e. All HCFCs are “Class II” ozone-depleting substances (ODS) subject to the phase out per the Montreal Protocol and U.S. Clean Air Act.

R22 Has Been Part of Phase Out Targets Since the 1990s

The point here is, this HCFC phase out was decided upon a long time ago and thereby this R22 refrigerant phase out is nothing new. In fact, it was in 1993 that the EPA established a phaseout framework and a “worst-first” approach. Thus, what made R-22 most ripe for a sooner phase out date (in comparison to all other HCFCS) was the fact that it had one of the highest ozone depletion potentials.

And what complicated this matter further was the fact, out of all the HCFCs being phased out (i.e., there’s 34 in total), R-22 was such a popular choice and one of the most widely used HCFC refrigerants. In fact, it’s used as a refrigerant in many different applications, including unitary air conditioners, cold storage, retail food refrigeration equipment, chillers, and industrial process refrigeration (IPR).

All of these applications are affected but not necessarily in the same way, which leads us to our next point:

Numerous Stakeholders Impacted by January 1, 2020 Phase Out Date

The impact from this phase out upon these applications has been unfolding for years, and it continues to unfold to present day.

But before we dive into the impact for each specific application, let’s address what you need to look out for in the near-term regardless of application:

- Limited supply;

- Rising prices; and

- Illegal usage.

It’s very true that, with less than 12 months to go until the phase out reaches completion, we may see the impact unfold more dramatically and unexpectedly in the weeks and months ahead. It’s best to know about the possibilities.

R22 Phase Out Has Far-Reaching Effects

That’s because supply is now very limited, which means prices are also steeply rising.

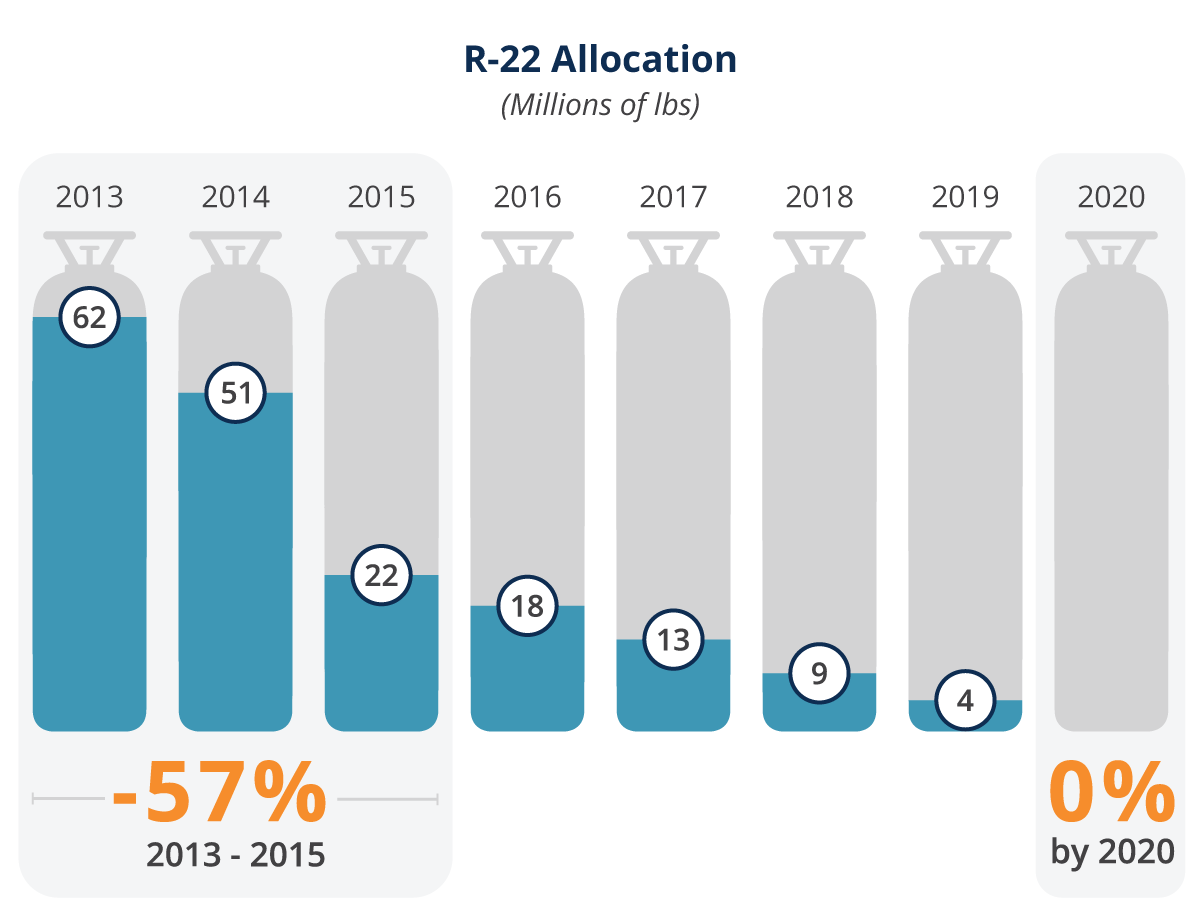

Per the EPA’s final phase out plan for R-22 (i.e., 79 FR 64253), the production and importation allocations are as follows:

- 51 million pounds in 2014;

- 22 million pounds in 2015;

- 18 million pounds in 2016;

- 13 million pounds in 2017;

- 9 million pounds in 2019; and

- No new or imported R22 on or after Jan. 1, 2020.

See the chart below for a visual representation of the R-22 allocation.

Though this phase out has been longed plan for, many stakeholders will and are still being taken by surprise. Take, for example, in the past six months alone, there have been numerous reports of illegal importing and selling of R-22. Accordingly, illegal usage is on the rise, and you should tread with caution in such a precarious time.

While this is a lot of information to take in, realize that there are several actions you can do in the near-term to mitigate the negative effects of the phase out.

Adhere to Industry Best Practices Now to Prepare for Future

You should be performing preventative maintenance and adhering to industry best practices now to prepare for the R22 refrigerant phase out.

Reduce Refrigerant Leak Rates

Preventative maintenance steps include proactively checking for refrigerant leaks with an electronic leak detector and keeping refrigerant leak rates low, so that the need to purchase additional R-22 is minimized as much as possible. While the allowable refrigerant leak rate depends on equipment type per EPA 608 (30% for industrial refrigeration; 20% for commercial refrigeration; and 10% for air conditioning), you should consider reducing your leak rates even further beyond the requirements.

Employ Refrigerant Analysis During Recovery

In addition, you need to adhere to refrigerant recovery best practices and requirements. With no new production of R-22 in 2020, the need to properly recycle R-22 will become paramount.

With limited R-22 supplies, the HVAC-R industry as a whole cannot afford to contaminate R22 refrigerant in the recovery process. This is where the importance of refrigerant analysis comes in.

For instance, a refrigerant analyzer, like the Neutronics Mini ID R-22 Refrigerant Identifier, takes the guesswork out of refrigerant recovery. Before recovery, you perform refrigerant analysis to ensure refrigerant is high concentration R-22. This allows the technician to properly recover the refrigerant in their R-22 recovery cylinder, preventing the likelihood of refrigerant contamination, which would lead to refrigerant destruction.

The more refrigerant that is destroyed means less for commercial use. This simple step of identifying the refrigerant before recovery will allow recycled refrigerant to be available more economically for the future and can also ensure technician safety and proper operation of system. In fact,

“It is not like the old days where there were only a handful of refrigerants. With so many options available, the only way to be certain is to begin to analyze refrigerants,”

Zach Ziegler, Product Line Manager at MSA Safety

It is not like the old days where there were only a handful of refrigerants. With so many options available, the only way to be certain is to begin to analyze refrigerants. You see, now that there are refrigerants with flammable properties on the market, use of an unapproved refrigerant could lead to injury concerns from burns or even explosions. Indeed, amid this phase out, there have been serious concerns about the wrong and unsafe use of alternative refrigerants being added to or retrofitted in an R-22 unit, which leads us to our next point:

Know Acceptable Alternative Refrigerants and Have a Long-term Plan

To state it simply, and in the end, you truly have three options:

- Continue to run the R-22 unit until no longer possible;

- Retrofit the unit to an acceptable alternative refrigerant; or

- Replace the unit with a new one.

There’s no one right answer.

What’s most important, though, is that you do have a long-term plan for the R22 refrigerant phase out. And no matter what that plan fully entails, it definitely needs to include the preventative maintenance steps and best practices discussed above.

If you do decide to retrofit, know that the acceptable alternatives depend on the end use. That’s why, for your convenience, we’ve decided to include some acceptable alternative refrigerant options for the residential air conditioning, retail food, and industrial process end uses. (Keep in mind that “alternative” or “replacement” refrigerant does not mean it can be used to top off existing refrigerant in the unit/system.)

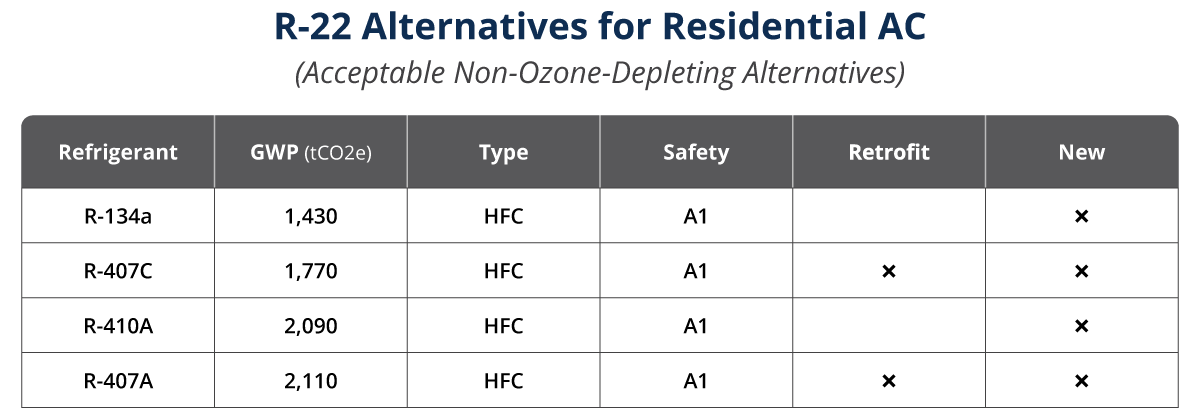

Residential Air Conditioning

Residential air conditioning comes first in this discussion because, in the coming months, this end use will be most affected by the phase out. Residential air conditioning includes equipment that cools enclosed spaces in households and commercial industries.

In the chart above, you will find a few acceptable alternative options, including R-410A, R-407A, and R-134a. And when you see an x, that means it is acceptable in new and/or retrofit equipment. Check out this page for a full list of EPA SNAP-approved alternatives for this end use.

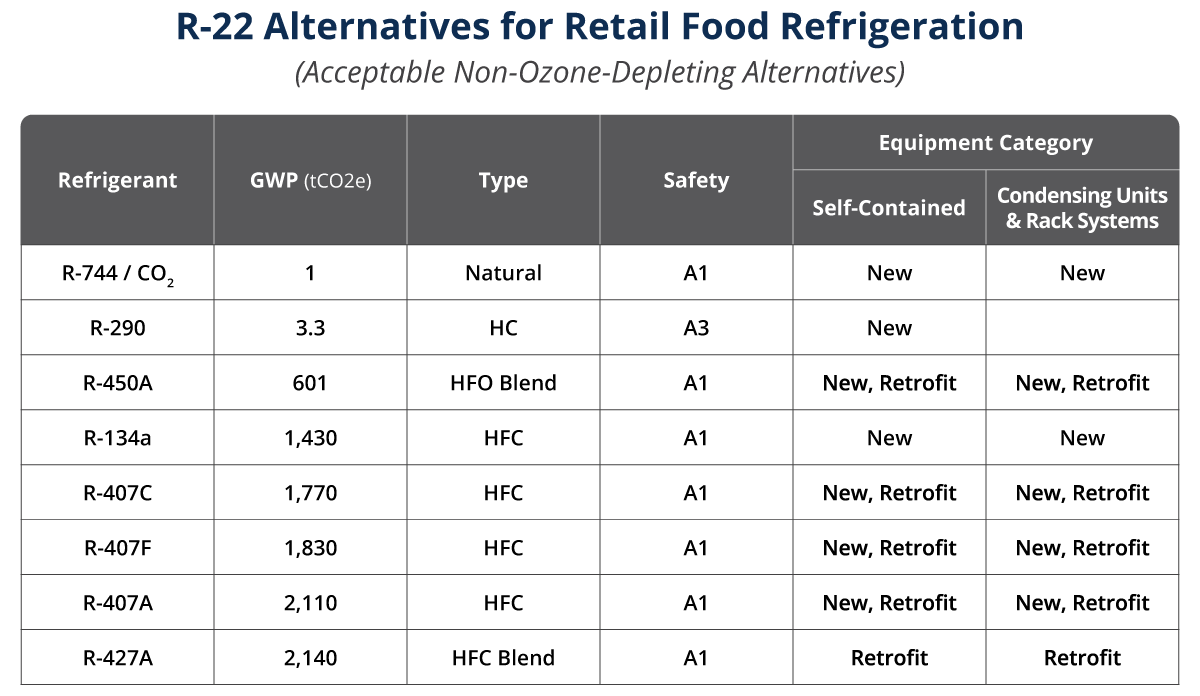

Retail Food Refrigeration

Retail food refrigeration includes stand-alone equipment, remote condensing units, and supermarket systems. To see a complete list of acceptable alternatives for this end use, see this page. The good news is that various stakeholders within the retail food refrigeration sector are probably the most well-informed and prepared for the R22 refrigerant phase out.

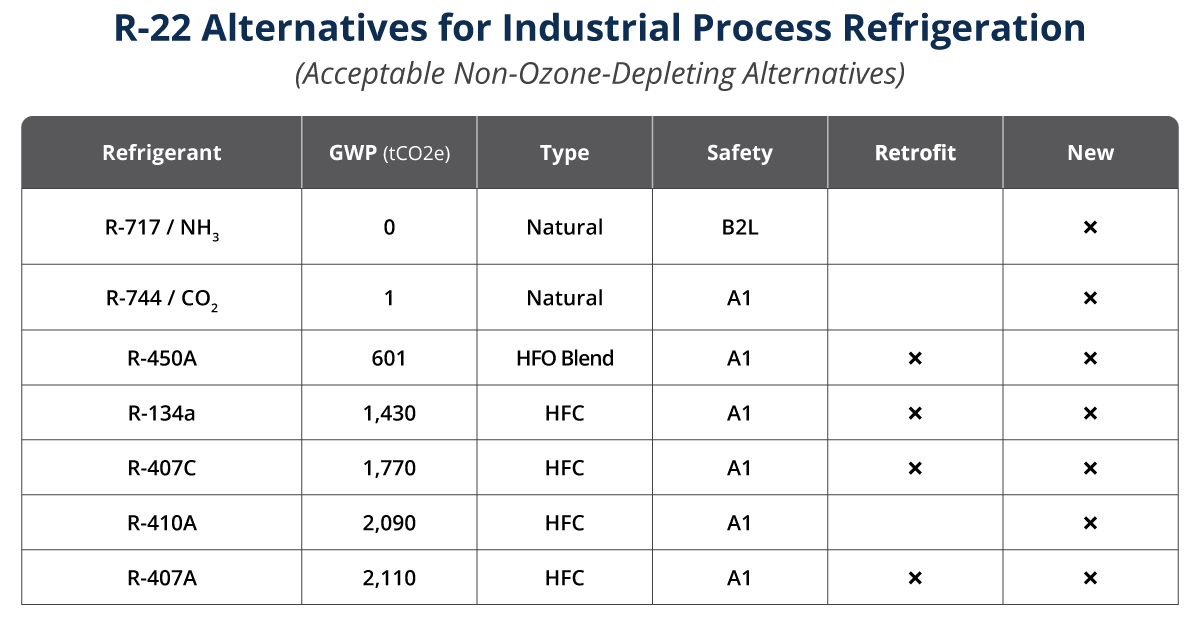

Industrial Process Refrigeration

When it comes to IPR, natural refrigerants (e.g., NH3 and CO2) especially are making a comeback. To see a full list of acceptable alternatives for IPR, check out this page.

Pay Attention to Equipment Type and Application With Alternatives

Please note that some alternatives are only acceptable in new equipment and other are acceptable in both new and retrofit equipment.

If and when you do perform a retrofit, make sure to properly recover any R-22 still in the equipment (which includes refrigerant analysis beforehand), follow manufacturer’s suggested handling and installation guidelines for that particular alternative, and understand that a conversion to a different refrigerant might affect performance and energy use.

Learn From This Phase Out and Proceed with Caution

Ultimately, it will be interesting to see how the final months of the R22 refrigerant phase out unfold. While there are many other regulatory factors that complicate this matter further (e.g., California’s new refrigerant regulations and the state of HFC refrigerants), the important thing is to learn from this phase out, proceed with caution, and do not do anything hastily.

If you follow the preventative maintenance steps and industry best practices found in this article, you are well on your way to being prepared in the near- and long-term.