Are you aware of the changes to the refrigerant cylinder color code? Those who maintain, service, repair, or dispose of HVAC-R equipment should be aware of the change to the Air-Conditioning, Heating, and Refrigeration Institute’s (AHRI) Guideline N, Assignment of Refrigerant Container Colors.

In fact, according to this guideline, all refrigerant containers (except for recovered and recycled refrigerants) are to have one uniform paint color, RAL 7044, by January 2020. Because we identified this issue as one of the top things to plan for in 2020, we thought it was important to provide additional details for HVAC-R stakeholders.

This article explores the following in relation to the refrigerant cylinder color code changes:

- Background on the change;

- What the revision to Guideline N entails; and

- the Importance of refrigerant safe-handling practices.

Refrigerant Cylinder Color Code

First, the purpose of AHRI’s Guideline N is for the assignment of refrigerant container colors.

What is the color designation?

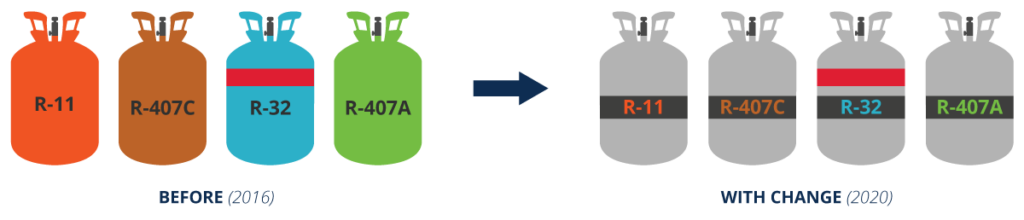

Originally, Guideline N stipulated different paint colors for refrigerant cylinders for quick and easy recognition, such as light green for R-22, orange for R-404A, light blue (sky) for R-134a, and rose for R-410A.

This color designation was meant to assist in refrigerant handling, help identify the type of refrigerants in cylinders and prevent their mixing. However, as more and more refrigerants entered the marketplace, the number of colors increased steeply, and confusion ensued.

One of the most obvious turning points was when the colors for some refrigerants started looking too similar. Take R-410A and R-502, for example, which have closely related colors (rose for the former; light purple for the latter) and could easily be mistaken for each other upon first glance.

Revision to Guideline N Announced

The point is, for many stakeholders, this color designation became confusing. In fact, “more than half of respondents to an AHRI survey of refrigerant users found that container colors had caused confusion.” Such concerns over confusion were bolstered by even more refrigerants being introduced on the marketplace and many of them having flammable properties and thereby increasing safety risks.

As a result, revisions to Guideline N were published in 2016 that called for all refrigerant containers (except for those recovered and recycled refrigerants) to have the same paint color, light gray-green RAL 7044, by 2020. Some refrigerant suppliers, like AirGas, implemented the change early on, announcing that it would transition cylinders in the first quarter of 2017.

Uniform Paint Color Takes Effect

The update, the 2017 Guideline for Assignment of Refrigerant Container Colors, makes clear that existing inventories are not required to be repainted, and flammable refrigerants must still have a red band on the top of the container. Additionally, AHRI will continue to assign Pantone Matching System (PMS) colors for printed materials only, including the label on containers and the outer packaging of DOT39 cylinders.

It’s important to note that this is a voluntary guideline (not a mandatory requirement) in the U.S. While it may be used in other countries (e.g., Latin America), it is also not a global guideline. Nonetheless, with only a handful of cylinder manufacturers on the market, we would expect to see wide adoption of this voluntary guideline.

Importance of refrigerant safe-handling

While we do not yet know the broader impact this change could have upon the HVAC-R industry, the most important takeaway from this update is that adhering to and employing refrigerant safe-handling best practices in your day-to-day activities is paramount.

The fact of the matter is, with so many new refrigerants on the market, there is a greater potential for mixed and counterfeit refrigerants. The mixing of refrigerants could negatively affect air-conditioning or refrigeration system operation and ultimately lead to more refrigerant destruction in place of recycling.

That’s why technicians must take their time in grabbing the right cylinder for the application in which they are working on. It cannot be the standard rhythm they are used to. Even more importantly, Zach Ziegler, Product Line Manager at MSA Safety, states, “Not only should technicians ensure they are grabbing the right cylinder, but they also should confirm the refrigerant required in the system.”

Not only should technicians ensure they are grabbing the right cylinder, but they also should confirm the refrigerant required in the system.

Zachary Ziegler, Product Line Manager at MSA Safety

The increased use of A2L and A3 class refrigerants has changed the game, as they come along with flammability risks. In fact, if one is not cognizant of a refrigerant and its appropriate application, there is a greater danger to life, limb, and/or property now, more so than ever before.

Ensure Refrigerant Quality

As such, contractors should avoid costly contamination of refrigerants. Employing methods to confirm the refrigerant required in systems as well as verifying what they have and what they should use on that system is important for safe and efficient operations.

Ultimately, make sure you are purchasing refrigerant from certified dealers to avoid counterfeits, and, when applicable, use a refrigerant analyzer to test all systems before recovery to ensure high quality refrigerant. Such refrigerant analysis is the safest and most efficient way for refrigerant identification and is a good investment for contractors.

Along similar lines, with the changes to the refrigerant cylinder code now in effect, it’s important to assess your application needs and see how you can make improvements to your own operations in terms of determining refrigerant purity.

It begins by answering questions such as:

- How long are you and your team spending on refrigerant identification now?

- What safety groups do the refrigerants you work on belong to (e.g., A1, A2L, B1, etc.,), and has there been an increase in servicing one group in recent years?

- Are you identifying refrigerant in the smartest and fastest way possible?

No matter how this color code change plays out in-the-field, investing in a refrigerant analyzer allows you to quickly and accurately determine refrigerant purity, preparing for the changes that lie ahead and the uncertainties that may come along.