In a world increasingly reliant on technology, the importance of functional safety cannot be overstated. Functional safety is a critical aspect of engineering that focuses on ensuring systems operate safely, reliably, and consistently, particularly in applications where failure could result in harm to people, damage to the environment, or financial losses. The convergence of cutting-edge technology and the harsh conditions of hazardous environments demands a specialized approach to functional safety.

What Is Functional Safety?

Functional safety refers to the ability of a system or product to reliably perform its intended function while minimizing the risk of causing harm. This concept is especially crucial in industries such as oil & gas, aerospace, and manufacturing, where the failure of a system could lead to severe consequences.

Importance of Functional Safety

Functional safety is paramount in various industries as it ensures that systems and equipment operate in a manner that prevents or mitigates the impact of hazardous failures. By systematically addressing potential risks and implementing safety measures, functional safety not only protects human lives and the environment but also enhances operational reliability, compliance with regulations, and overall organizational reputation. Prioritizing functional safety is an investment in both risk reduction and the long-term sustainability of operations.

Functional Safety Standards

Functional safety standards, such as the widely recognized IEC 61508 and IEC 61511, provide a structured framework for designing, implementing, and maintaining systems to achieve functional safety. These standards establish guidelines for hazard analysis, risk assessment, and the development of safety functions, ensuring a consistent and systematic approach that helps organizations meet regulatory requirements, reduce operational risks, and foster a culture of safety-conscious design and engineering. Compliance with functional safety standards not only enhances the reliability of critical systems but also instills confidence among stakeholders and end-users in the safety and dependability of products and processes.

Functional Safety Life Cycle

The functional safety life cycle extends from component level to system level monitoring for assurance of reliability throughout useful life. Achieving functional safety involves a comprehensive life cycle approach at both component and system levels, including the following key phases:

-

Requirements

Identifying key attributes of design with consideration to potential hazards and assessing associated risks is the first step in functional safety. This involves a thorough safety function analysis of each relevant component in the system including potential failure modes and diagnostic capabilities.

-

Design

Designing each component of the system with safety in mind, incorporating performance reliability, diagnostics, fail-safe mechanisms, and appropriate control strategies.

-

Validation and Testing

Rigorous testing is essential to validate that the system meets functional safety requirements. This includes simulation, testing of individual components, and system-level testing.

-

Documentation and Compliance

Keeping detailed records of the design decisions, safety analysis, and testing results is crucial for on-going support and maintenance of each relevant component of the system.

-

Maintenance and Monitoring

Continuous monitoring of the system’s performance and implementing regular maintenance ensures that safety integrity is maintained over the system’s lifecycle.

Challenges in Achieving Functional Safety

Achieving functional safety poses challenges such as the complexity of modern systems, requiring intricate analysis and rigorous testing to identify potential failure modes. Integration of safety measures can be challenging, especially in systems where multiple components interact. Additionally, maintaining functional safety over the entire lifecycle of a system requires continuous monitoring, periodic maintenance, and adaptation to evolving technologies and operating environments, demanding a commitment to ongoing diligence and expertise from design to decommissioning.

Conclusion

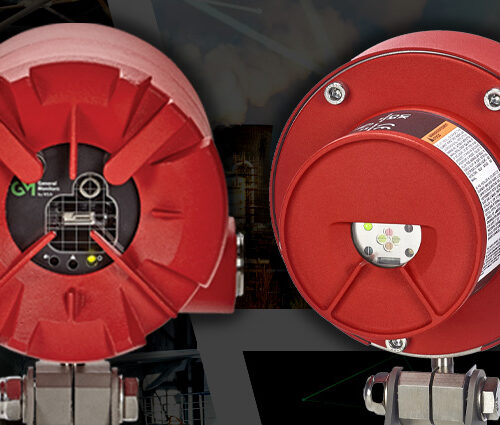

In fire and gas detection systems, functional safety is crucial for preventing catastrophic incidents. Functional safety standards guide the design and implementation of these systems, ensuring their reliability in detecting and mitigating gas leaks or flame occurrences. Compliance with functional safety standards in this context is not just a regulatory necessity; it is a fundamental assurance that these critical safety systems will operate effectively, providing early warnings and alarms enabling timely responses to prevent accidents and protect personnel and assets in environments where gas and flame hazards exist.

Functional safety is a critical consideration in the design and operation of systems across various industries. As technology continues to evolve, the need for robust functional safety practices becomes even more apparent. Engineers and organizations must prioritize safety in their designs, adopting a comprehensive life cycle approach and staying abreast of evolving standards and technologies to ensure that their systems operate safely and reliably in a constantly changing world.