When it comes to designing a flame detection system, the Field of View (FoV) of each detector is a critical parameter that directly impacts coverage, cost-efficiency, and overall system reliability. By understanding how FoV is impacted by flame characteristics, installation environment, and detector technology, engineers can make better informed decisions about the number, placement, and type of detectors.

What Is Field of View in Flame Detection?

Field of View refers to the effective area a flame detector can monitor for the presence of fire, based on response test data to certain fire sizes. Typically expressed in degrees (e.g., 90°, 120° horizontal) and range, a wider FoV allows a detector to “see” more of the surrounding space. However, a wider view doesn’t automatically mean better performance—it must be matched to the application’s requirements and environmental conditions.

Why FoV Matters

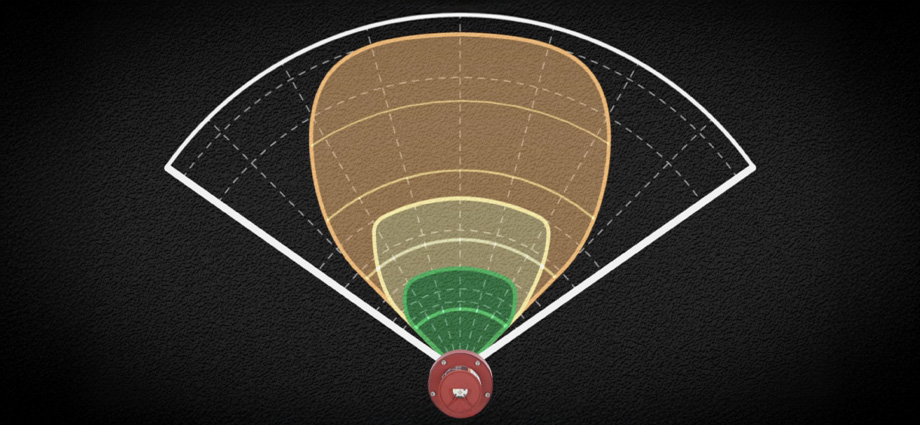

A wider FoV allows a flame detector to monitor more horizontal and vertical space, but the coverage area is also determined by range—the maximum distance at which a flame of a given size and type can be reliably detected. For example, a detector with a 120° FoV and a 60-foot (18-metre) range will cover a much larger area than one with the same FoV but a 30-foot (9-metre) range.

Both FoV and range work together to define the effective detection zone. Optimizing these parameters helps reduce blind spots, minimize overlap, and enable full area protection with the fewest number of detectors.

A mapping study—often performed during the design phase—can help identify blind spots, assess potential reflection or absorption issues, and confirm that every critical zone is covered. These studies consider detector range, angle, mounting height, fuel type, and environmental conditions to maximize detection reliability and system effectiveness.

A narrower FoV may help isolate detection to a defined zone, minimizing interference from non-targeted sources of ultraviolet or infrared radiation.

Factors That Affect Effective FoV

While manufacturers specify a nominal FoV, real-world performance depends on several factors:

- Fuel Type

Different fuels produce different flame signatures. For example, methane and hydrogen flames behave very differently in terms of size, intensity, and spectral output. These differences impact how far and wide a detector can reliably “see” a flame. - Detector Sensitivity Settings

Sensitivity can be adjusted to detect smaller flames or prioritize a longer range. However, increasing sensitivity may also raise the potential for false alarms. - Environmental Conditions

Dust, fog, sunlight, or reflections from nearby surfaces can all influence detection performance and effective coverage.

Visualizing Coverage with Flame Detector Simulators

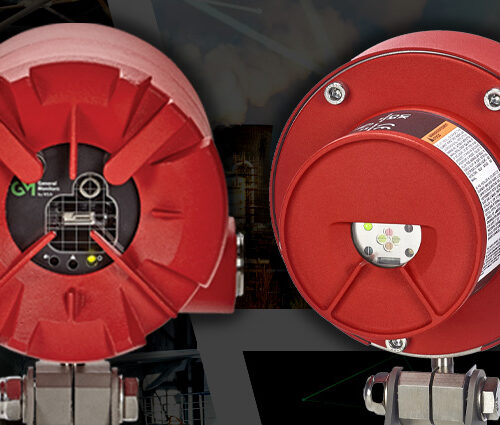

To help engineers and system designers optimize detector placement, MSA offers Field of View Simulators for the FL5000 MSIR and FL500 UV/IR flame detectors. These interactive tools let you visualize how coverage is affected by:

- Specific fuel types (e.g., n-heptane, propane, methane)

- Detector sensitivity settings

The simulator provides a visual representation of the detection zone—helping you determine the number and orientation of detectors needed for comprehensive coverage.

Optimizing Detector Placement

To make the most of your flame detectors:

- Use simulation and mapping tools to preview and plan your layout.

- Match FoV to your hazard area—don’t assume wider is always better.

- Consider redundancy where obstructions or high-risk zones are present.

- Validate the layout during commissioning to confirm line-of-sight and adequate coverage.

Final Thoughts

The Field of View is more than just a technical specification—it’s a key design variable that affects safety, compliance, and total cost of ownership. By leveraging tools like the FL5000 and FL500 simulators, you can build smarter fire detection systems tailored to your facility’s unique risks and layout.

Ready to explore your application?

Try our new FL5000 Field of View Simulator and see the difference configuration makes.