Many industrial settings harbor hazardous areas that can pose significant risks to workers, equipment, and the environment. Understanding and properly managing these hazards is crucial for maintaining a safe and productive workplace. So what constitutes a hazardous area? Hazardous areas in industrial settings are characterized by the presence of potentially dangerous substances or conditions that can lead to fire, explosion, or other safety hazards. The classification of hazardous areas typically depends on the types of materials or processes involved. Here are some common factors that contribute to the classification of a hazardous area:

- Flammable Gases or Vapors: Areas where flammable gases, vapors, or mists are present in sufficient quantities to ignite or explode. Examples include areas around fuel storage tanks, gas pipelines, or where volatile chemicals are used or stored.

- Flammable Liquids: Locations where flammable liquids with low flashpoints are used, stored, or handled. This can include areas near fueling stations, paint booths, or chemical storage areas.

- Reactive Chemicals: Areas where reactive chemicals, such as strong acids, oxidizers, or unstable compounds, are present. These chemicals can react violently with other substances or release toxic gases, leading to hazardous conditions.

- High-Pressure Systems: Areas where high-pressure systems exist, such as pipelines, vessels, or hydraulic systems. The release of pressurized gases or liquids can cause mechanical failure or create dangerous conditions.

- Confined Spaces: Enclosed or partially enclosed spaces, such as tanks, vessels, or storage bins, where the accumulation of flammable or toxic gases can occur. Lack of ventilation can lead to hazardous atmospheres.

- Extreme Temperatures: Areas with extreme temperatures, either very high or very low, which can pose risks to personnel or equipment. Examples include furnaces, ovens, or cryogenic storage areas.

Reliable Sources for Safety Information

To help ensure safety in hazardous areas, industrial facilities must adhere to local regulations and industry standards. For comprehensive and up-to-date information, consider consulting the following reliable sources:

- Occupational Safety and Health Administration (OSHA): OSHA is a regulatory agency in the United States that provides guidelines and regulations related to workplace safety. Their website offers valuable insights into hazardous locations and related regulations.

- National Fire Protection Association (NFPA): NFPA develops codes and standards related to fire safety, including hazardous locations. Their publication NFPA 70 (National Electrical Code) contains vital information on hazardous locations and electrical safety. Access their website for more details.

- International Electrotechnical Commission (IEC): IEC is an international standards organization that provides guidelines and standards for electrical systems and equipment. Their publication IEC 60079-10-1:2015 covers the classification of hazardous areas and offers guidance on selecting and installing electrical equipment. For further information, visit their website.

Conclusion

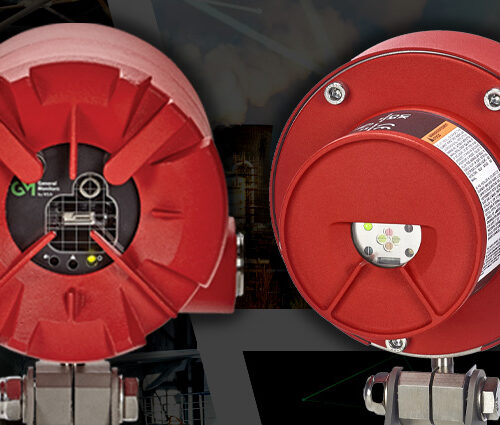

To ensure safety in hazardous areas, various measures are employed, including the use of explosion-proof equipment which include fixed gas and flame detectors, ventilation systems, safety barriers, and proper training for personnel. It’s important for industrial facilities to comply with local regulations and standards related to hazardous areas to help minimize the risk of accidents and protect workers and the environment.

Understanding hazardous areas in industrial settings is crucial for maintaining a safe work environment and preventing accidents that could lead to severe consequences. By becoming familiar with the factors that contribute to hazardous areas and relying on authoritative sources for guidance, you can help ensure the safety and well-being of workers and the surrounding environment. Emphasizing safety not only helps protect lives but can also boost productivity and confidence in the workplace. Remember, when it comes to hazardous areas, knowledge is power, and safety is paramount.